-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

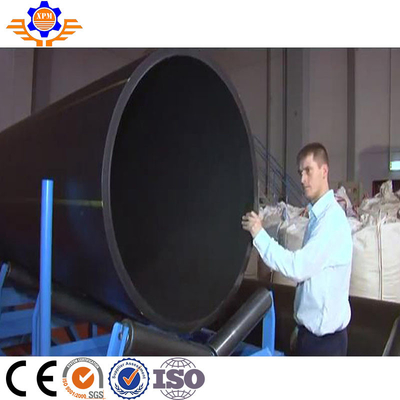

Plastic PP PE Pipe Production Line with output 16 - 315mm PE Plastic Pipe Extruder

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150Kg/H | Motor Power | 55Kw |

| Highlight | 16mm PE Pipe Extrusion Line,1200mm PE Pipe Extrusion Line,55Kw hdpe pipe manufacturing machine |

||

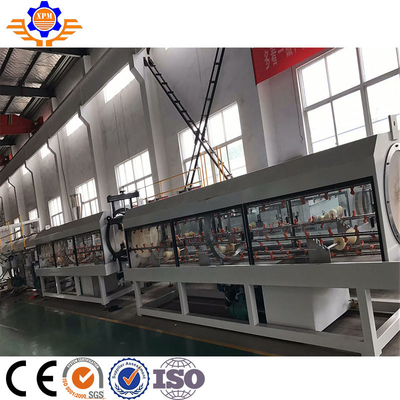

Plastic PP PE Pipe Production Line with output 16 - 315mm PE Plastic Pipe Extruder

Quick detail:

1. Simple follow chart:

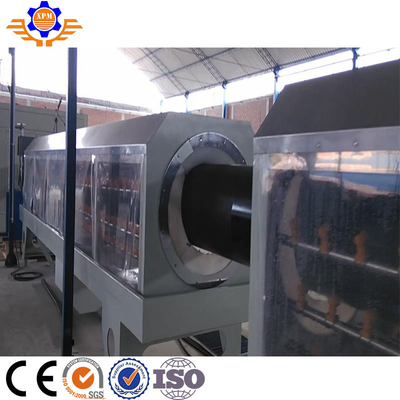

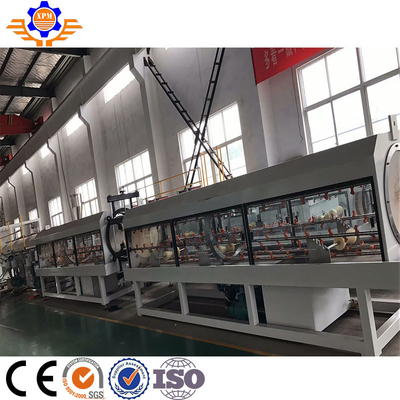

Vacuum feeding machine---- Dry hopper ----- Single screw extruder----- Mould ----- Vacuum tank ----- Water tank----Haul off ---- Double disk winding machine

![]()

2. Characteristics:

a) Man-machine operation interface, high automation level

b) The adoption of professional screw ensures good plastification

c) Adopts compound screw type head to clear memory function effectively

d) Vacuum forming, constant temperature control to remove stress of pipe material

e) Adopts common extruding head and adds marking color line for pipe material.

Description:

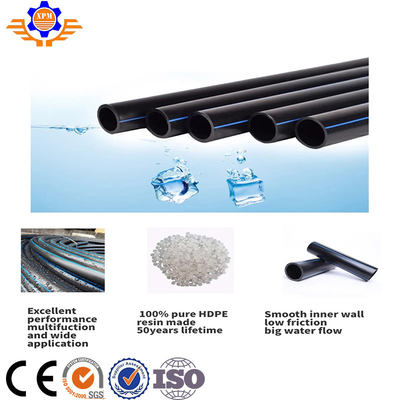

1. HDPE / PE Pipe is mainly used in the area of the agricultural water supply system, architectural water supply and drainage system, pavement of cables and gas supply etc.

2. Good components: Siemens Beide main motor, ABB inverter, Eurotherm DC regulator, Siemens & Schneider low voltage electrics, Omron temperature controller

3. Good design and good outlook: We design the machine for easier operation and stable performance. The haul-off machine and cutter is fully closed for safety purpose. Planetary socket is using in some machines for wire connection.

4. PP/PE Production Line is mainly used in the production of agricultural drainage, water supply and drainage, and cable laying,etc. purposes. The unit consists of a conical double/ parallel double extruder, mold, vacuum forming tank, multi-claw haul-off machine, planetary(chipless) cutting machine, stacker and so on. And the line can be equipped with a Comptroller thickening instrument or computer inkjet printer, etc. to achieve the production and manufacture of high-grade tubing.

Specifications:

| Extruder | Main motor(KW) | Pipe range (mm) | Capacity(kg/h) |

| SJ65/33 | 45-55 | 16-110 | 80-150 |

| SJ75/33 | 90-110 | 90-250 | 200-300 |

| SJ90/33 | 160 | 160-315 | 450-500 |

Competitive Advantage:

experience: Our company have more than 15 years’ experience in designing and manufacturing extrusion equipment; the core technology and equipment are communicating and docking with the advanced European plastics processing technology

Market: Our products have been sold all over China and exported to countries all over the world, such as Russia, Ukraine, Armenia, Azerbaijan, Uzbekistan, Kazakhstan, Italy, Romania, Australia, Turkey, Iran, Pakistan, India, Bangladesh, Indonesia, Japan, Vietnam, Mexico, Venezuela, Brazil, Peru, South Africa, Egypt, Tunisia, and so on.

After Sales Service: We offer turnkey project,technicians will be sent to buyer's factory for installation and commissioning of the equipmnet and training of workers;all you maintenance requirements to equipment will be replied within 24 hours.

![]()