-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

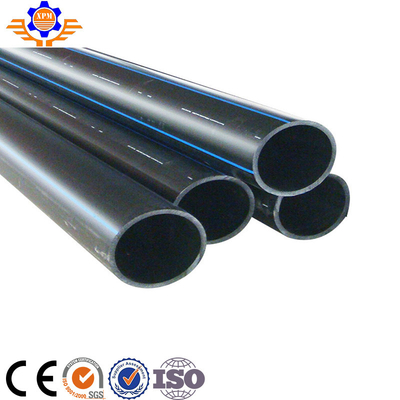

Natural Gas Pe Corrugated Pipe Making Machine Single Screw Extruder

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150Kg/H | Motor Power | 55Kw |

| High Light | HDPE pe corrugated pipe making machine,Natural Gas pe corrugated pipe making machine,110KW hdpe pipe production line |

||

PE NATURAL GAS TUBE EXTRUSION MACHINE WITH SINGLE SCREW EXTRUDER

Application:

Water and gas supply, micro&sprinkler irrigation system, sewerage pumping and effluent disposal system.

Properties & Advantages:

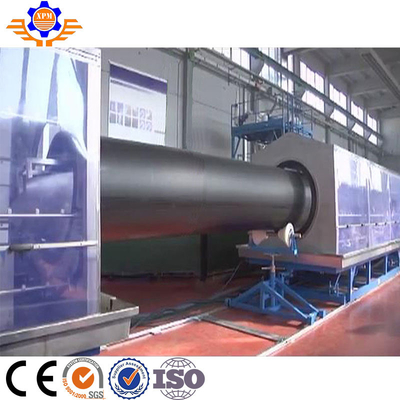

The pipes produced by this line have excellent hardness and flexibility. Their diameters vary from 16mm to 1200mm. The line consists of control system, extruder, die, vacuum calibration unit, hauling-off and planetary cutting system and stacker.

Two extruders are utilized in this line. The main extruder is used to extrude the large diameter pipes and the other small one is used to extrude the mark line.

Basket or spiral type composite die is used in this line. PLC control system and large chromatic liquid crystal screen make the operation very convenient.

![]()

Process flow:

Raw material+master batches--mixing--vacuum feeding--material dryness--single screw extruder--mark line extruder---mould--calibrator---vacuum spray calibration tank---spray cooling water tank---color-ribbon printer--pedrail haul-off--planetary cutter--stacker---finished product inspecting&packing

SPECIFICATIONS:

| MODEL | PIPE DIAMETER (MM) | EXTRUDER MODEL | MOTOR POWER |

| XPM-63 | 20-63 | SJ65/33 | 55AC |

| XPM-110 | 20-110 | SJ65/33 | 55AC |

| XPM-160 | 75-160 | SJ75/33 | 90AC |

| XPM-250 | 90-250 | SJ75/33 | 110DC |

| XPM-315 | 110-315 | SJ90/33 | 160DC |

| XPM-450 | 160-450 | SJ90/33 | 160DC |

| XPM-630 | 315-630 | SJ120/33 | 280DC |

| XPM-800 | 500-800 | SJ150/33 | 315DC |

| XPM-1200 | 710-1200 | SJ150/34 | 400DC |

![]()

All Extrusion pipe lines can be equipped with various auxiliary equipments in order to meet our customer’s requests and provide solution from a single source.

| Volumetric and gravimetric dosing units |

| Raw material loading units |

| Belling machines |

| Corrugators |

| Ink jet marking units |

| Winding units |

| Tilting tables |