-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

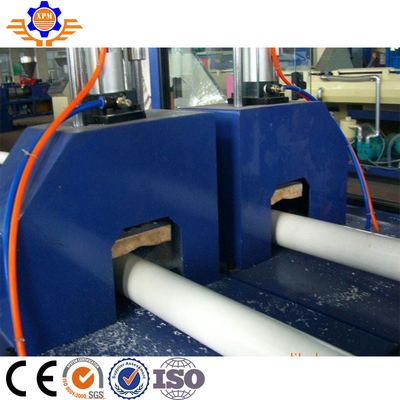

Pressure PVC Pipe Extrusion Line Adjustable Cutting Speed Max 63mm Cutting Pipe

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 450Kg/H | Motor Power | 55Kw |

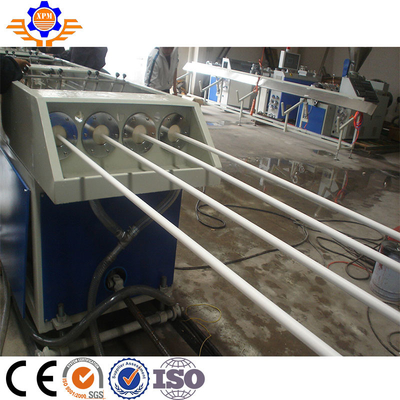

PVC /UPVC ELECTRICAL CONDUIT PIPE MACHINE FOUR STRANDS DIAMETER 16-32MM

Production Description:

Low Invest /Stable Output UPVC/CPVC/PVC Plastic Pipe Production Extrusion Line adopts friendly interface, intelligent control, it is convenient for use and reliable in working. The screw,gear-reducer and mould are specially designed for high temperature,high viscosity,difficult plasticization of the PVC/CPVC melt and ensure the continuous production with stability. The finished product widely used in drainage, electricity cable transportation etc. It can extrude the single wall pipe, foamed core pipe, inner spiral pipe with one, or more cavities pipe extrusion.

![]()

Specifications:

| Model |

Screw diameter(mm)

|

Main motor power (kw)

|

Max output(kg/h)

|

Calibrating length(mm)

|

Mode of haul-off | Cutting mould |

Pipe diameter(mm)

|

| SJG-110/50 | 51/105 | 22 | 180 | 4000 |

two rubber belt

|

saw cutting

|

Φ50-110 |

| SJG-200/160 | 65/132 | 37 | 250 | 4000 |

three rubber belt

|

saw cutting

|

Φ160-200 |

| SJG-400/250 | 80/156 | 55 | 380 | 6000 | four rubber belt |

planet cutting

|

Φ250-400 |

| SJG-630/400 | 92/188 | 90 | 600 | 6000 | six rubber belt |

planet cutting

|

Φ400-630 |

Applications:

Low Invest /Stable Output UPVC/CPVC/PVC Plastic Pipe Production Extrusion Line adopts friendly interface, intelligent control, it is convenient for use and reliable in working. The screw,gear-reducer and mould are specially designed for high temperature,high viscosity,difficult plasticization of the PVC/CPVC melt and ensure the continuous production with stability. The finished product widely used in drainage, electricity cable transportation etc. It can extrude the single wall pipe, foamed core pipe, inner spiral pipe with one, or more cavities pipe extrusion.

which is high-intensity,high temperature-resistant,chemical-resistant,insulate and flame retardant. The pipe is the best choice for protect power cable and have good prospects.

![]()

Advantage of the UPVC/CPVC pipes:

1.Non-toxic: no heavy metal additives, not be covered with dirt, not be contaminated by bacterium.

2.Corrosion Resistant: resist chemical matters or electron chemical corrosion.

3.Lower Installation Costs: light weight and ease of installation can reduce installation costs by as much as 50% over metal piping system.

4.Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

5.Long Life: more than 50 years under normal conditions.

6.Recycled and Environment-friendly.

![]()

![]()