-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

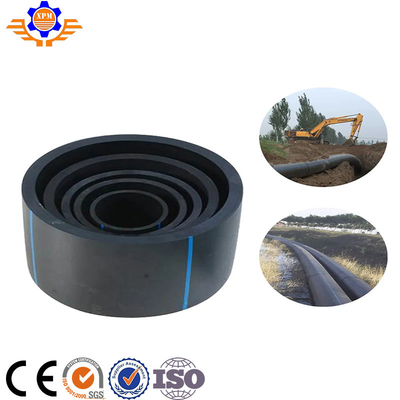

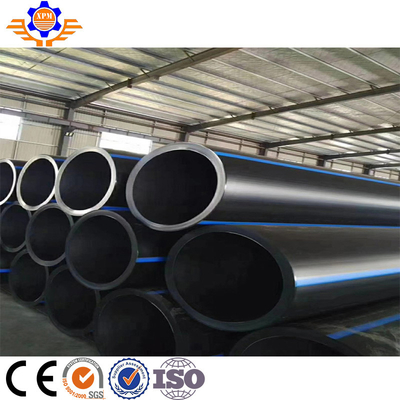

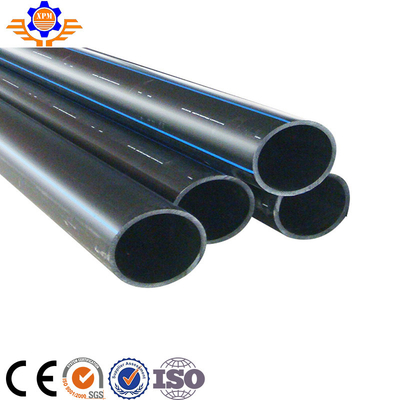

20 To 630mm Tube PE PP Pipe Extrusion Line Automatic HDPE Plastic Pipe Production Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150Kg/H | Motor Power | 55Kw |

| Highlight | 20mm PP Pipe Extrusion Line,630mm PP Pipe Extrusion Line,HDPE plastic pipe production line |

||

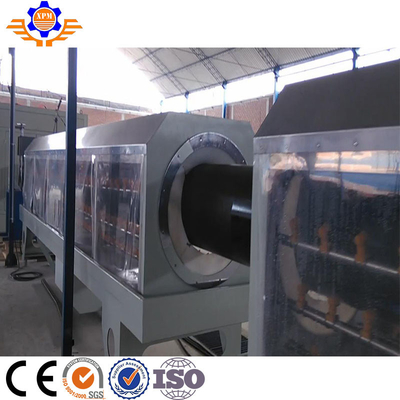

PE Pipe Extrusion Line PE/PP tube production machine line

Product:

We Offer pe/pp tube production machine line with CE and ISO9001:2000 Certificate

20-630mm plastic pipe Extrusion line for you

Product name: PE/PP tube production machine line

Feature:

The production line is mainly used by pipe producing line which adopts also PP-R resin as raw material, besides, it is suitable for pipe production adopting PP, PPB, PPC, PE, ABS resins as raw materials.

![]()

1. Man-machine option interface and high automation level

2. It adopts a special screw stem to make good plastic-fiction result

3. It adopts compound screw type head to clear memory function effectively;

4. Vacuum forming, constant temperature control to remove stress of pipe material;

5. It adopts common extruding head, adding marking color line for pipe material.

![]()

Technology Parameter:

| Unit Model | SJPG-65 | SJPG-90 | SJPG-120 |

| Main motor power(kw) | 30-37 | 55-75 | 90 |

| Cylinder heating power(kw) | 23 | 34 | 48 |

| Length-diameter ratio | 30:1 | 30:1 | 30:1 |

| Production capacity(Kg/h) | 80-100 | 120-150 | 200-220 |

| Vacuum pump power(kw) | 5.5 | 7.5 | 7.5 |

| Water pump power(kw) | 4 | 4 | 4 |

| Mobile motor power(kw) | 0.75 | 0.75 | 1.1 |

| Drawing motor power(kw) | 3 | 4 | 5.5 |

| Cutting motor power(kw) | 2.2 | 2.2 | 3 |

| Power(kw) | 72 | 110 | 160 |

| Equipment arrangement length(mm) | 30 | 36 |

42

|

Specification:

| MODEL | PIPE DIAMETER (MM) | EXTRUDER MODEL | MOTOR POWER |

| XPM-63 | 20-63 | SJ65/33 | 55AC |

| XPM-110 | 20-110 | SJ65/33 | 55AC |

| XPM-160 | 75-160 | SJ75/33 | 90AC |

| XPM-250 | 90-250 | SJ75/33 | 110DC |

| XPM-315 | 110-315 | SJ90/33 | 160DC |

| XPM-450 | 160-450 | SJ90/33 | 160DC |

| XPM-630 | 315-630 | SJ120/33 | 280DC |

| XPM-800 | 500-800 | SJ150/33 | 315DC |

| XPM-1200 | 710-1200 | SJ150/34 | 400DC |

Equipment:

All Extrusion pipe lines can be equipped with various auxiliary equipment in order to meet our customer’s requests and provide solution from a single source.

| Volumetric and gravimetric dosing units |

| Raw material loading units |

| Belling machines |

| Corrugators |

| Ink jet marking units |

| Winding units |

| Tilting tables |

Our Services:

Pre-sales service:

- Introducing in detail features and application of the products to customer

- Selecting economical and practical machine & equipment for customer

- Providing operation data of the related machine & equipment

- Providing means of trial performance for customer

Sales service:

- Recommending engineering conditions required for installation of the machine & equipment

- Communicating in time the manufacturing progress of the machine with the user

- Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-sales service:

- Providing on-the-spot technical assistance in installation, commission and training

- Filling in detail customer’s information

- Providing long-term maintenance service and spare parts

- Giving technical support to customer for developing new product

- Providing free maintenance for a year

![]()

Our Advantages:

1.Saijia is a high-tech enterprise specializing in the production of plastic processing complete sets of equipment and various plastic pipe moulds, integrating scientific research, development, manufacturing, sales and service.

2. The company integrates the rich design and manufacturing experience accumulated by the sophisticated technical team over the years, with advanced production equipment technology, strict quality assurance measures, scientific management methods, fast and efficient service, and constantly blaze new trails to meet the needs of customers. Products sell well all over the country and exported to many overseas countries and regions won the trust of all parties, the product is in the same industry-leading position in the country.