-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

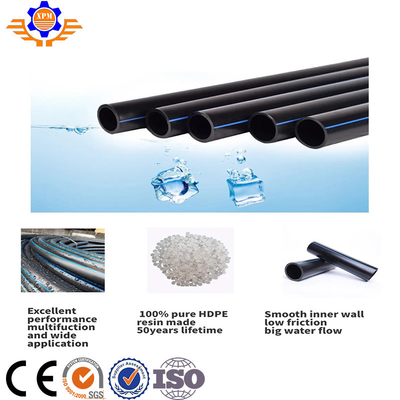

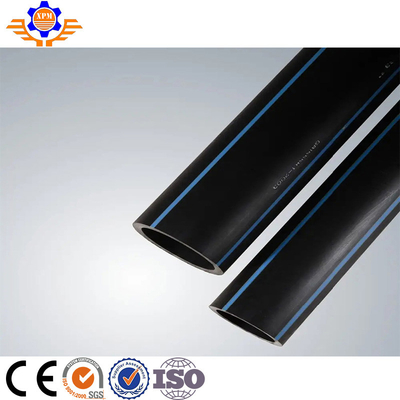

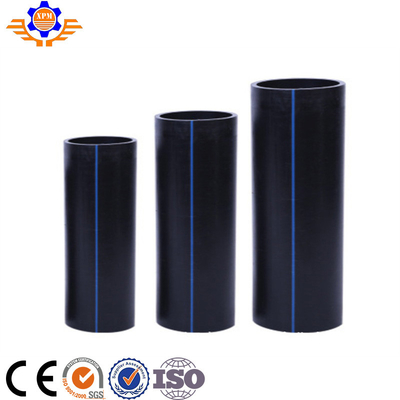

16 To 110MM Tube PE Pipe Extrusion Line 55Kw PPR Pipe Making Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150Kg/H | Motor Power | 55Kw |

| Highlight | 16mm PE Pipe Extrusion Line,110MM PE Pipe Extrusion Line,55Kw ppr pipe making machine |

||

HDPE PE PPR PP pipe extrusion machine/making machine/production line

Processing:

Hopper Dryer and Auto charger → PE pipe extruder → marking line extruder → mould → calibrator → vacuum calibration tank → spray cooling water tank → printer → haul-off → cutter → pipe discharging rack

Our Features

1. Equipped with XPM single or twin screw extruder, it can fulfill the need of processing PVC, PP, PE, ABS, PMMA et cetera.

2. 3-Dimension adjustable vacuum calibrating unit, optimized vacuun swith, flow switch, multiple choice of dies.

3. Optimized designed tooling, precise fabricated, high quality material.

4. Dynamic balance haul-off, frequency conversion/AC speeding, stable running, convenient operation.

5. Cutter adopts professional designed saw blade, controlled by PLC, smooth flat cut.

6. Optimized length counter and dust collector configuration.

![]()

Parameter:

| PE-63 | 65mm | 33:1 | 16-63 | 37 | 80 | 24 |

| PE-110 | 65mm | 33:1 | 75-110 | 55 | 110 | 30 |

| PE-160 | 75mm | 33:1 | 90-160 | 90 | 150 | 32 |

| PE-250 | 75mm | 33:1 | 110-250 | 110 | 200 | 42 |

| PE-315 | 90mm | 33:1 | 160-315 | 160 | 240 | 44 |

| PE-400 | 90mm | 33:1 | 200-400 | 185 | 300 | 50 |

| PE-500 | 120mm | 33:1 | 250-500 | 280 | 350 | 56 |

| PE-630 | 120mm | 33:1 | 315-630 | 280 | 480 | 56 |

| PE-800 | 150mm | 33:1 | 400-800 | 315 | 550 |

72

|

Question and answer

Q: Your company is a transactional company or an industrial manufacture factory?

A: We are an industrial manufacture factory which locates in Zhangjiagang city.

Q: All of your products are made by your self or compacted via purchasing the others?

A: We have independent technical team who focus on making machines, all the products are made by our technical team.

Q: What is the ability of your factory?

A: About 90 lines per year.

Q: Do you have any other services about your products?

A: We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

Q: How do you make the quotation for clients?

A: The price depends on quality and performance but the clients should be satisfied first.

Why choose us:

1. Low cost : all the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality : we choose our material very strict, all the material come to our factory must pass the quality test substandard goods are returned to the supplier.

3. Engerneers available to serve oversea:

4. Quick delivery: the company provide just in time delivery with its streamlined supply chain

5. Cost saving we take strong attention to every detail in the manufacturing process,the quality control in our factory is very strict, all defective semi-manufactures must be treated again or reject. all the machine must be checked out ,then deivered to our customer. all about that pushing up the price, what we want to do is give our customer a good quality product with stable working and long lived.