-

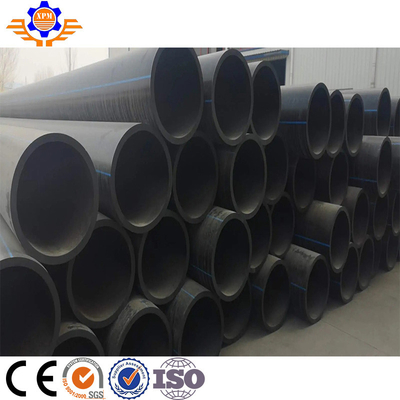

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

20-63MM PE Pipe Extrusion Line Vacuum Calibration Sleeves 160KW Single Screw Plastic Extruder

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150Kg/H | Motor Power | 55Kw |

| Highlight | 1000 kg/h PE Pipe Extrusion Line,Hot Water PE Pipe Extrusion Line,twin screw plastic extruder ISO9001 |

||

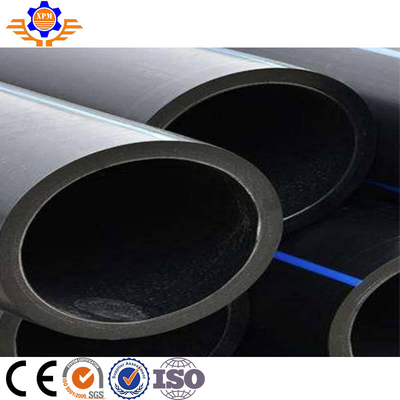

PE HOT WATER AND HEATING PIPE EXTRUSION LINES WITH VACUUM CALIBRATION SLEEVES

Product Application:

SJ series single screw extruder, is suitable for PP, PE and other thermoplastic special-shaped material, plate, sheet, rod, and plastic granulation processing.According to different raw materials and products specifications, screw with different length to diameter ratio and compression ratio, barrel with different structure.Choose the right machine barrel, screw and drive mechanism, in order to satisfy the demands of the processing of high quality products.

The Single Screw Extruder is designed for the PE and PP pipe applications.

We target to provide the optimal solutions for the customer’s special needs with the advantage of flexibility in material choices, high performance and long durability.

High flexibility in raw material combinations

Gentle and homogeneous plastification

Different screw geometries for customer’s special needs

Barrel with air cooling system

AC motors for low energy consumption

Control panel with color touch screen

Product Range

Screw diameters from to 45 to 160 mm

L/D ratios from 30:1 to 36:1

Outputs from 85 to 1650 kg/h

All Extrusion pipe lines can be equipped with various auxiliary equipments in order to meet our customer’s requests and provide solution from a single source.

Saijia presents fully automatic pipe coilers for three different dimensions as 16mm-32mm , 20mm-63mm and 50mm-125mm. As an option, we can add Pipe Diversion Unit to our torque controlled coilers if required.

As the coiling finished, with the help of the mechanism which allows to co¬nnect the egde of the pipet to the rill, the connection to the rill has became easier.

With their working speeds and adjustable torque values, our coilers are also suitable for the Natural Gas Pipe production and they also provide a safe and a quality coiling processr

![]()

With PLC Touchscreen Panel Control Unit, Kuatro-Plast coilers allows you to control the diameter of the coiled pipe, speed and torque values easily

Thank to their PLC Controller, the coilers which we especially produced for the diameters 16-32mm and 20-63mm, work syncronized with the production line with no problem.

All Extrusion pipe lines can be equipped with various auxiliary equipments in order to meet our customer’s requests and provide solution from a single source.

Volumetric and gravimetric dosing units

Raw material loading units

Ink jet marking units

Winding units

Tilting tables

![]()

SPECIFICATIONS:

| MODEL | PIPE DIAMETER (MM) | EXTRUDER MODEL | MOTOR POWER |

| XPM-63 | 20-63 | SJ65/33 | 55AC |

| XPM-110 | 20-110 | SJ65/33 | 55AC |

| XPM-160 | 75-160 | SJ75/33 | 90AC |

| XPM-250 | 90-250 | SJ75/33 | 110DC |

| XPM-315 | 110-315 | SJ90/33 | 160DC |

| XPM-450 | 160-450 | SJ90/33 | 160DC |

| XPM-630 | 315-630 | SJ120/33 | 280DC |

| XPM-800 | 500-800 | SJ150/33 | 315DC |

| XPM-1200 | 710-1200 | SJ150/34 | 400DC |