-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

220V 380V Wood Plastic Composite Extrusion Line PVC Marble Artificial Stone Production Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 50-320Kg/H | Motor Power | 37Kw |

| High Light | 220V wood plastic composite extrusion line,380V wood plastic composite extrusion line,PVC artificial stone production line |

||

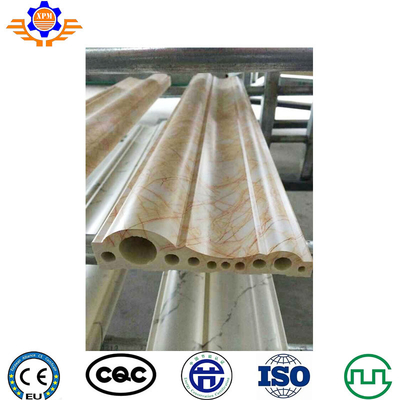

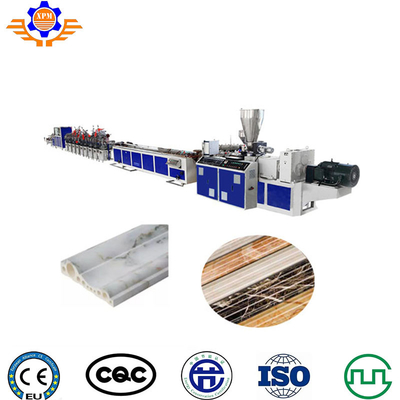

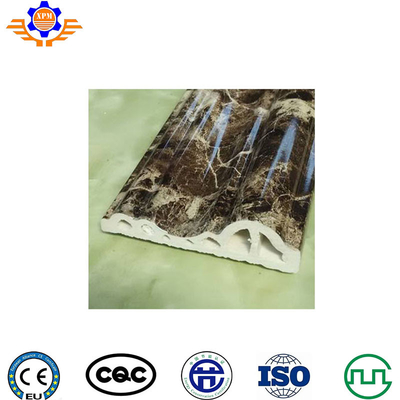

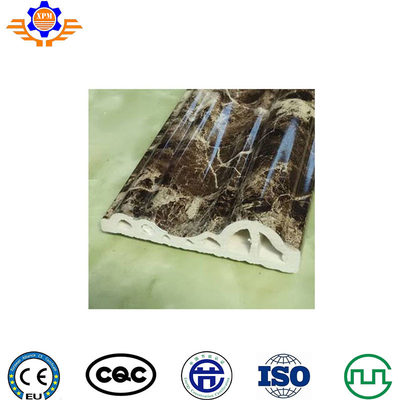

Marble Profile Wood Plastic Composite Extrusion Line , PVC Marble Profile Machine

![]()

Quick detail:

1.Recycled material, low cost

2.Beautiful decorative board

3.Waste recycling plant

Description:

![]()

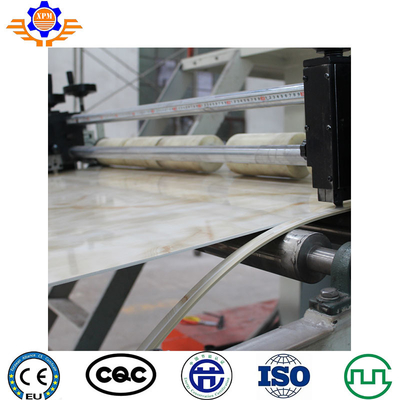

Taking advantages of its practical, affordable and simple features, this wood texture vinyl flooring is widely applied to home, office, school, supermarket and hospital as the ideal decoration material. As a high quality vinyl plank, it has stood the test of time and market.

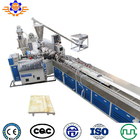

1.Well designed well made high quality extruder with special use helical gear reducer and high efficiency converter motors, make high speed extrusion, single screw for PP PE material, conical double screw for PVC material;

2.Special screw structure, high shear stress and low temperature, ensure high quality plasticization;

3.High precise T-type die head, indepedent oil temperature control chromed 3-roller calender, uniform speed and high traction force NBR roller haul-off machine help making uniform thickness PVC PP PE sheet;

4.Whole line with high degree of automation, easy to operate;

5.High quality steel materials, strict producing process make high quality line;

6.New advanced energy saving technology, lowered energy consumption;

7.Whole line adopt newest design concept, using well known brand electrical components, enhanced line stability

![]()

Applications:

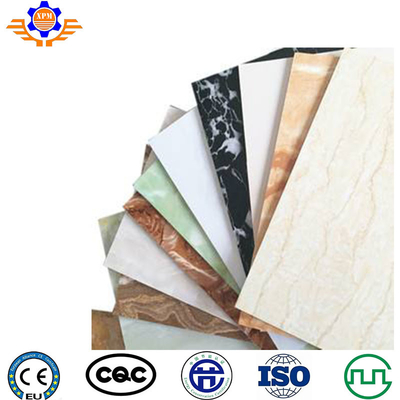

1. Lots of colors and color consistency

2. Never seeped oil

3. Large surface application

4. Natural & Attractive appearance

5. Nice heat and sound insulation

6. Fade resistance

7. No radiation, Non-toxic and eco-friendly features

8. Easy installation, renewable character and competitive price

Specifications:

| Model | SJSZ65/132,SJSZ80/156,SJSZ92/188 |

| usage | extrusion outdoor decorative |

| raw material | recycled PE/PP,wood powder, additive material,etc |

| product size | maximum:400mm,or according to prdroduct’s drawing |

| Extruder feature | Special designed extruder |

| wood powder ( wood fiber) | high volume of addition up to 50~75 percent |

| Plastic proceed | PP,PE,PVC,wood plastic composite |

| Auxiliary machine | Emboss machine,sanding machine,polishing machine |

| Product type |

Dustbin, Sound insulation board (wall),edging,blinds,bulkhead,curtain rod, |

Competitive Advantage:

International Approvals

High Quality with Factory Price

Fast Delivery Service

Good After-sale Service

![]()