-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

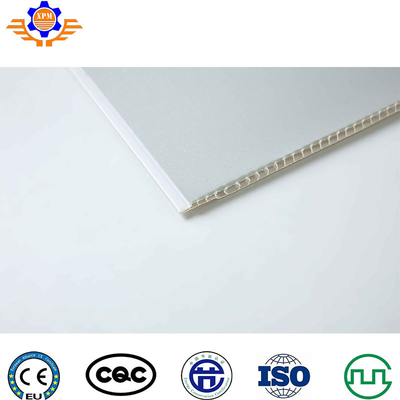

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

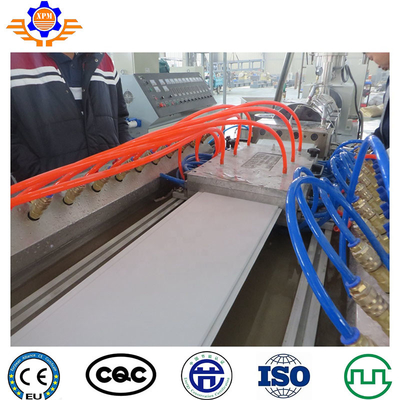

320Kg/H Plastic Trunk PVC Wall Panel Extrusion Line Plastic Profile Machinery

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC,WPC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Decorative Materials |

| Output | 150-320Kg/H | Motor Power | 37Kw |

| Highlight | 320Kg/H PVC Wall Panel Extrusion Line,ABB PVC Wall Panel Extrusion Line,37Kw pvc profile extrusion machine |

||

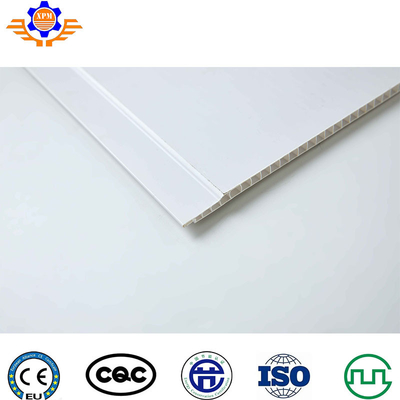

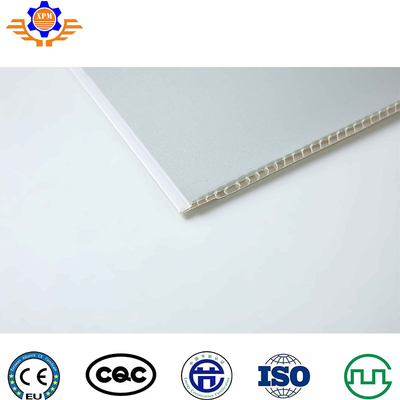

PVC Trunk Plastic Profile Extrusion Line , PVC Wall Panel Plastic Profile Machinery

Brief introduction:

This PVC profile machine include:extruder,mould,vacuum calibration table,haul-off machine,cutter and stacker. According to the different profile section and mould design, varied models of twin screw extruder and downstream equipments can be optional.

Description:

1. Raw plastic material: recycled plastics (PVC, PE, PP) and wood fiber (wood powder and other plant fiber such as rice bran, straw, etc. )

Main raw material (the two accounted for more than 90%) produce wood plastic composites (WPC).

2.The product has the following advantages:

1) Wood-plastic composite materials instead of full-wood products, protecting forest resources.

2) Wood-plastic composites can use the stalks of plants, reducing environmental pollution

3) Wood-plastic composite material to eliminate white pollution, cleaning up the natural environment

3. This PVC window profile extrusion line is designed for extrusion of PVC plastic door's and window's profiles and cross-section communication cable pipes, Aluminum-plastic composite profiles, etc.

![]()

Applications:

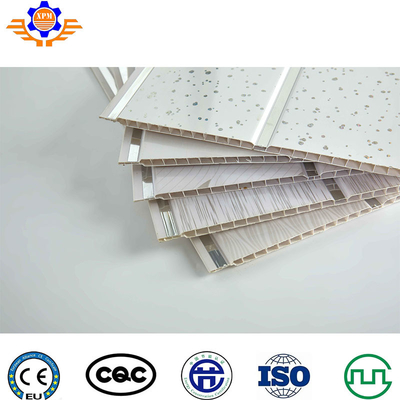

YF series PVC profile extrusion line is mainly used for extrusion of PVC window and door profile, wood-plastic profile, plintus, wall panel and ceiling panel, electrical conduit trunking channel, decorating profile ect.

![]()

Specifications:

| Model | SJSZ65/132,SJSZ80/156,SJSZ92/188 |

| usage | extrusion outdoor decorative |

| raw material | recycled PE/PP,wood powder, additive material,etc |

| product size | maximum:400mm,or according to prdroduct’s drawing |

| Extruder feature | Special designed extruder |

| wood powder ( wood fiber) | high volume of addition up to 50~75 percent |

| Plastic proceed | PP,PE,PVC,wood plastic composite |

| Auxiliary machine | Emboss machine,sanding machine,polishing machine |

| Product type | Dustbin, Sound insulation board (wall),edging,blinds,bulkhead,curtain rod, |

Competitive Advantage:

It has stable plastification, high output, low sheering force, long life service and other advantages. PVC profiles can be used in the building industry and home or office.