-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

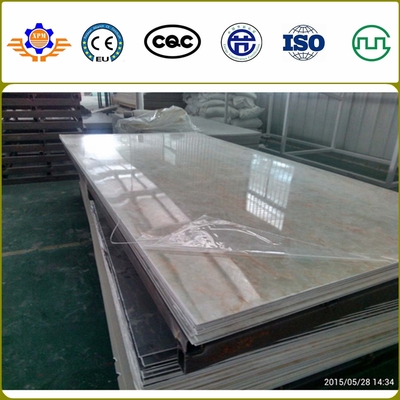

1220mm PVC Marble Sheet Making Machine PLC Control ABB Inverter Siemens Motor

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 380V Or Customized | Application | Plastic Pipe |

| Output | 400Kg/h | Motor Power | 75kw |

| High Light | PVC Marble Sheet Making Machine,1220mm Artificial Marble Production Line,PLC Control PVC Marble Sheet Machine |

||

PVC Artificial Marble Board/Sheet Panel Extrusion Making Machine Production Line Extuder

![]()

we continue to perfect the PVC artificial marble sheet production line , design more reasonable , easy operate , the artificial PVC marble sheet production line can produce single layer PVC marble sheet or multi-lays PVC marble sheet , it equip with the 3-rollers calibration device to ensure the mini thickness 0.3mm , and max thickness to 10mm , the production line consist the main machines : feeder , extruder , mold , 3-roller calibration , cooling rack , hauling off machine , cutter , etc .

Description:

![]()

PVC marble sheet surface adopt laminating the PVC pattern foil film or hot stamping process , it make the PVC marble sheet surface looks same as the natural marble , for the film and sheet are same raw materials , so it can ensure the PVC decoration marble sheet has the big advantages :

1. The surface and the sheet stick firmly , and the surface shine and wonderful

2. fire retardant , moistureproof , acid resistance , corrosion resistance , long-term service life , no formaldehyde and other toxic volatile substance, no peculiar smell ,

3. mildew proof , water repellent

4. the PVC imitation marble sheet can be processed same as wood , like drill , saw , nail , plane etc.

![]()

we adopt the top quality spare parst : SIEMENS motor , ABB converter , SCHNEIDER electric parts, etc. we supply the turn-key service include installation , testing run and training workers in your local factory .

we continue to perfect the PVC artificial marble sheet production line , design more reasonable , easy operate , the artificial PVC marble sheet production line can produce single layer PVC marble sheet or multi-lays PVC marble sheet

![]()

Specifications:

| Model |

SJSZ80/156,SJSZ92/188 |

|

usage |

extrusion with laminating |

|

raw material |

PVC + Caco3 |

|

product size |

maximum:1220mm normally ,or customized |

|

Extruder feature |

Special designed extruder |

|

electric |

Schneider |

|

main motor |

75kw |

|

process |

feeder , extruder , mold , 3-roller calibration , cooling rack , hauling off machine , cutter |

|

Product type |

artifical PVC marble sheet |

Competitive Advantage:

International Approvals

High Quality with Factory Price

Fast Delivery Service

Good After-sale Service