-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

220Kg/H PVC Profile Extrusion Machine With Conical Double Screw Plastic Extruder

| Place of Origin | ZHANGJIAGANG,CHINA |

|---|---|

| Brand Name | XPM |

| Certification | CE,ISO |

| Model Number | XDXC180/240/300/400/500 |

| Minimum Order Quantity | 1 SET |

| Price | 40,000-50,000 USD/SET |

| Packaging Details | WOODEN CASE PACKING AND PLASTIC FILM |

| Delivery Time | 45 WORKING DAYS |

| Payment Terms | T/T |

| Supply Ability | 20 SETS PER MONTH |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150-320Kg/H | Motor Power | 37-110Kw |

| Highlight | 220Kg/H PVC Profile Extrusion Machine,PVC Profile Conical Twin Screw Extruder,380V PVC Plastic Extruder |

||

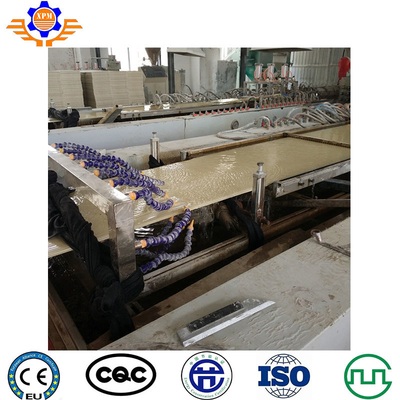

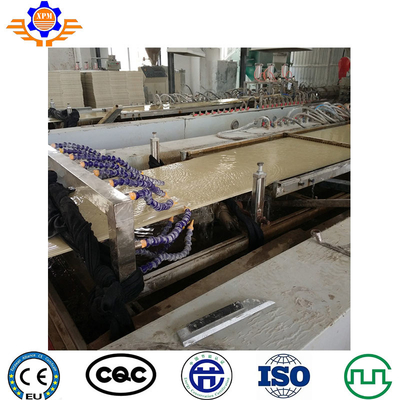

220Kg/h Pvc Profile Extrusion Machine With Conical Double Screw Plastic Extruder

1. PVC Ceiling panel extrusion line description:

PVC ceiling panel extrusion line consists of control system conical twin screw extruder, extrusion die, calibration unit, haul-off unit, cutting machine and stacker. This PVC ceiling production line has compact good plasticization, high output capacity, long life and other advantages If change some parts and die head, this PVC ceiling panel extrusion line also can produce other PVC profiles.

Features of PVC Ceiling panel:

1. Protection of the pig partition.

2. farrowing crate.

3. Fireproof and flame retardant

4. High intensity, resist erosion, anti aging and Convenient Installation

5. Fireproof, Heat Insulation, Moisture-Proof, Soundproof, Waterproof

6. Easy Setting and Cleaning

7. Good electric insulation, there is Metal-free, good electrical insulation and thermal stability.

8. Good mechanical strength. The hollow board can be cut, sawing, nailing, which is convenient for the further processing of installation

9. Good flexibility, easy to shape, not easy to brittle.

10. Saving labor costs, Light weight, easy installation, reducing the workload of workers, saving installation costs.

The complete extrusion consists of following items:

Conical Twin Screw Extruder:

It is used for melting and stirring plastic material. SAIJIA adapts special screw and barrel type that provide perfect mixing and homogenous. We use special gear box for the Extruder which has axial bearings. Transfer the motor to the screw. For minimizing electricity consumption, we use the famous brand of driving motor of “SIEMENS” on our Extruder. Automation system designed with PLC and touch panel controller can be selected.

![]()

- Mould: Our mould designing gives ideal viscosity to melt material for profile producing. It gives profile or shape to plastic after processing. All faces the plastic in contact with is polish, so that frication losses minimized.

- Calibration Table:The shaped profile that come from mould is subjected to calibration and cooling processing on the calibration table. The designing of calibration table varies according to the type and characteristic of the profile. The area that contacts with water is made of stainless steel in order to prevent corrosion.

- Caterpillar Haul-off: The designing of caterpillar haul-off changes depending on the contact area that is related to the profile measurement. The inverter control is standard on all caterpillar haul-off. For this reason, as the speed can adjusted with respect to material output rate. The caterpillar haul-off is also capable of making measurement adjustment through speed control equipment.

- Saw cutter: In the speedy working condition, profile saw works with high efficiency in term of cutting frequency. As the saw table and clamps move synchronously. The saw cuts the profile in required length. During the cutting processing, swarf and dust appears, in order to prevent these in production area, there is a dust collection unit is integrated in saw cutter. This unit absorbs swarf, dust effectively and removes to storage.

- Tip-off unit: It operates on pneumatic cylinder.

- Our extruder lines allow our clients to produce a wide range of PVC and WPC profiles with the following specifications:

![]()

PVC Ceiling Panel Extrusion Line Parameter:

| Model | XPM-200 | XPM-300 | XPM-600 |

| Max. Width | 220mm | 350mm | 600mm |

| Extruder Model | SJSZ-51/105 | SJSZ-55/110 | SJSZ-65/132 |

| Motor Power | 18.5kw | 22KW | 37KW |

| Max. Output | 120kg/h | 150kg/h | 250kg/h |

| Compressed Air | 0.2m3/h | 0.3m3/h | 0.5m3/h |

| instalaltion power | 45KW | 55KW | 67KW |

PVC profile extrusion line technical parameters:

| Extruder Model | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 | ||

| Mian motor power | 22kw | 37kw | 55kw | 110kw | ||

| Auxiliary machine | YF200 | YF240 | YF300 | YF600 | YF900 | YF1200 |

| Production width | 200 | 240 | 300 | 600 | 900 | 1200 |

| vacuum power | 4kwX1 | 5.5kwX1 | 5.5kwX1 | 5.5kwX2 | 5.5kwX1 7.5kwX1 | 5.5kwX1 7.5kwX1 |

| water pump | 2.2kw | 2.2kw | 4kw | 5.5kw | 7.5kw | 7.5kw |

| hauling speed | 0-5m/min | 0-5m/min | 0-5m/min | 0-3m/min | 0-2.5m/min | 0-2.5m/min |

| capacity | 150kg/h | 250kg/h | 250kg/h | 350kg/h | 600kg/h | 600kg/h |