-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

500-550pcs/24h 1.22m PVC Artificial Marble Extrusion Line Sheet Machine ABB Inverter

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 380V Or Customized | Application | Plastic Pipe |

| Output | 400Kg/h | Motor Power | 75kw |

| High Light | PVC Artificial Marble Production Line 380V,1.22m Marble Making Machine,ABB Inverter Marble Sheet Extrusion Line |

||

500-550pcs/24h 1.22m PVC Artificial Marble Extrusion Line Sheet Machine ABB Inverter![]()

we continue to perfect the PVC artificial marble sheet production line , design more reasonable , easy operate , the artificial PVC marble sheet production line can produce single layer PVC marble sheet or multi-lays PVC marble sheet , it equip with the 3-rollers calibration device to ensure the mini thickness 0.3mm , and max thickness to 10mm , the production line consist the main machines : feeder , extruder , mold , 3-roller calibration , cooling rack , hauling off machine , cutter , etc .

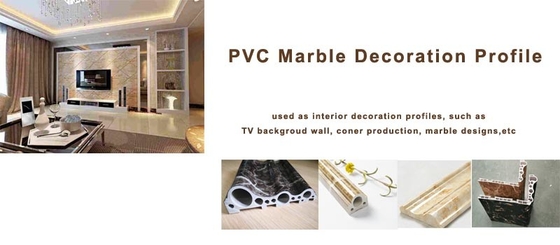

Description:

![]()

PVC marble sheet surface adopt laminating the PVC pattern foil film or hot stamping process , it make the PVC marble sheet surface looks same as the natural marble , for the film and sheet are same raw materials , so it can ensure the PVC decoration marble sheet has the big advantages :

1. The surface and the sheet stick firmly , and the surface shine and wonderful

2. fire retardant , moistureproof , acid resistance , corrosion resistance , long-term service life , no formaldehyde and other toxic volatile substance, no peculiar smell ,

3. mildew proof , water repellent

4. the PVC imitation marble sheet can be processed same as wood , like drill , saw , nail , plane etc.

![]()

we continue to perfect the PVC artificial marble sheet production line , design more reasonable , easy operate , the artificial PVC marble sheet production line can produce single layer PVC marble sheet or multi-lays PVC marble sheet , it equip with the 3-rollers calibration device to ensure the mini thickness 0.3mm , and max thickness to 10mm , the production line consist the main machines : feeder , extruder , mold , 3-roller calibration , cooling rack , hauling off machine , cutter , etc .

Specifications:

| Model |

SJSZ80/156,SJSZ92/188 |

|

usage |

extrusion with laminating |

|

raw material |

PVC + Caco3 |

|

product size |

maximum:1220mm normally ,or customized |

|

Extruder feature |

Special designed extruder |

|

electric |

Schneider |

|

main motor |

75kw |

|

process |

feeder , extruder , mold , 3-roller calibration , cooling rack , hauling off machine , cutter |

|

Product type |

artifical PVC marble sheet |

Competitive Advantage:

International Approvals

High Quality with Factory Price

Fast Delivery Service

Good After-sale Service