-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

320Kg/HR PVC Artificial Marble Production Line SGS Plastic Profile Pvc Profile Extrusion Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 400Kg/H | Motor Power | 73Kw |

| High Light | 320kg/Hr Artificial Marble Board Extrusion Machine,SGS Plastic Profile Extrusion Line,PVC Artificial Marble Extrusion Machine |

||

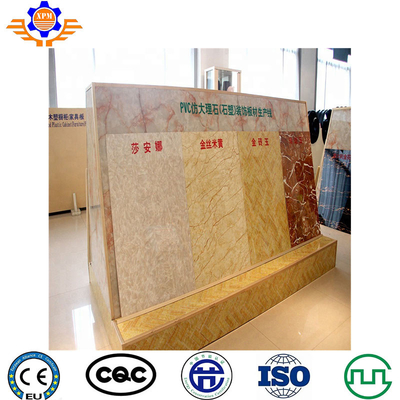

PVC Marble Plastic Profile Production Line / Plastic Profile Marble Extrusion Line

![]()

Quick detail:

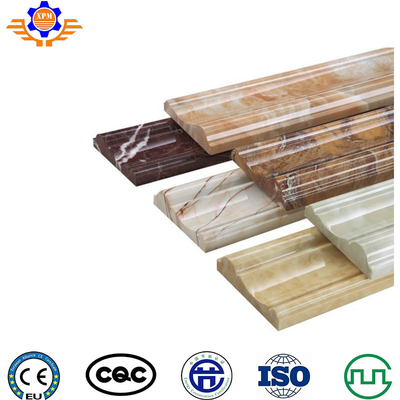

1. This production line is mainly used to produce PVC marble designs decorative profile, building materials, such as baseboard, doorjamb, electric cable trunk, door frame, decorative sheet , etc.

This building material is comparable to natural stone material, it's graceful and elegant at the same time with natural stone incomparable advantages.

2. Feature:

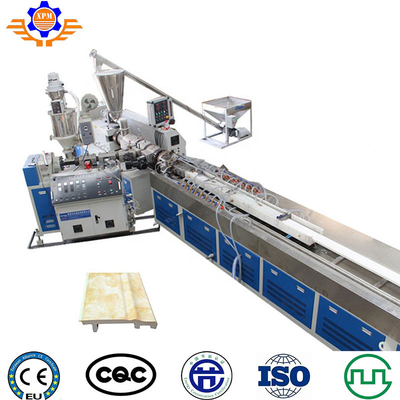

Conical twin-screw extruder, suitable for processing PVC powder and combination materials.

Changing the moulds to produce many kinds of different PVC building materials, decorative profiles.

Auxiliary machine: Mixing unit, Mould, Vacuum calibration table, Printing machine, Haul-off machine, Cutter and Stacker.

![]()

Description:

1. PVC Marble main application:

1)Now PVC marble and sheet is widly used and instead of traditional stone marble step by step.

2)Similar with traditional stone marble usage,it is used for wall,floor,window sill,TV background wall,wall corner skirting line and so on.

2. Advantages of PVC marble than traditional stone marble:

1)Environment protection,PVC marble is mainly made by PVC powder and Caco3 powder,it's environmental.Traditional stone marble has formaldehyde,toxic harmless also has radiocontamination.

2)PVC marble raw material is PVC powder and Caco3 powder,very cheaper than traditional stone marble.

3)PVC marble is water proof,but traditional stone is easy to got water seepage.

3. Process flow:

Mixer→Spiral loader→SJSZ51;SJSZ65;SJSZ80 double-screw extruder→mould→vacuum calibration spraying platform→haul-off machine→blade cutter→stacker

![]()

Technical Parameters:

| Items | YF180 | YF240 | YF300 | YF600 | YF900 | YF1200 |

| Max width of board(mm) | 180 | 240 | 300 | 600 | 900 | 1200 |

| Drawing heighe(mm) | 150 | 150 | 150 | 150 | 150 | 150 |

| Drawing speed(KN) | 2 | 2 | 2 | 30 | 40 | 50 |

| Drawing speed(m/s) | 0-5 | 0-5 | 0-5 | 0-3 | 0-2.5 | 0-2.5 |

| Auxiliary equipment sum power(kw) | 35 | 35 | 30 | 30 | 40 | 45 |

| Cooling water consume | 6 | 6 | 6 | 9 | 12 | 15 |

| Compression air(Mpa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Applications:

It is mainly used for producing various sizes of WPC PVC profiles, window door profile, decking floor, ceiling panel and so on. Our PVC profile machine has features of low consumption, high output, stable running.

Normal PVC profile production line is composed of main extruder, mould, vacuum calibration table, haul-off, cutting and stacker.

By changing different mould, PVC profile making machine can produce many PVC plastic profile products with different shapes.

Competitive Advantage:

24 hours services;

Overseas installation;

Free operation training and technology formula transfer;

Old machine update;

Spare parts and maintenance with reasonable cost price.