-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

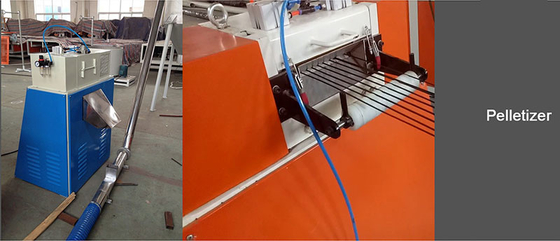

Pe Pp Waste Plastic Recycle Granules Production Making Line Pellets Pelletizing Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE/PP/PET/PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Granules |

| Output | 60-300Kg/H | Motor Power | 37Kw |

| Highlight | 380V Plastic Granules Machine,220V Plastic Granules Machine,15KW waste plastic recycling pelletizing machine |

||

Advanced Pe Pp Waste Plastic Recycle Granules Production Making Line Recycle Pellets Pelletizing Machine

Plastic Pelletizing and Granules Making Machine

The Advantages of Plastic Film Flakes recycling and pelletizing machine

1,High practicable for kinds of waste plastics recycling like plastic films, sheets and style material. 2,Equipped with non- stop filter net hydraulic changing for high automation and better output. 3,Particular features have granules from this machine with good plastic performance.

![]()

![]()

| Screw Dia.(mm) | Φ65mm | Φ90mm | Φ120mm | Φ150mm |

| L/D | 25-30:1 | 25-30:1 | 25-30:1 | 25-30:1 |

| Screw rotation (r/min) | 50-80 | 50-80 | 50-80 | 50-80 |

| Main power(KW) | 15 | 22 | 30 | 45 |

| Output (kg/h) | 60-80 | 100-120 | 150-200 | 200-300 |

![]()

●Ability:

SAIJIA pelletizing system with superior quality which have high productivity for PP/PE plastic could get high property output pellets.

●Stability:

The pelletizing system is available for 24 hours working non-stop operation.

●Efficiency:

The pelletizing system have very low consumption values for electricity, water and labor.

●Control:

Intelligent automatic control of pelletizing system reduces the labor operation, makes the whole system easier and more reliable to control.

●Service:

Consistently quick and careful service in pre-sales and after-sales process. Overseas installation, commissioning and training are available.

![]()

Similar Products

![]()

Company Profile

![]()

Zhangjiagang Saijia was established in 2000. The production experience is mature and rich. Among them, it has been exporting for more than 20 years, and more than 100 countries have exported. The annual export turnover is about 15 million US dollars. Our company's production base covers more than 50,000 square meters. , Modern office and production room more than 35,000 square meters, with experienced high-quality staff team, first-class equipment, perfect and effective quality assurance system, advanced and complete testing equipment.

Workshop

We know the quality is the life of our company. Our company insists to manufacture all machine units by ourselves in order to control quality strictly by our quality inspectors. To implement this concept, we have built our own tooling and CNC workshop. Even if some parts from our certified supplier, our quality inspector will check these parts before entering into our warehouse.

Warmly welcome to visit our workshop, and sincerely hope we can have long term cooperation in near future!

![]()

Certificates

International certification, verification certificates of equipment include:CE electrical certificate, CE mechanical certificate, ISO quality management certificate, Nigerian quality certificate etc.

![]()

FAQ

1) Are we manufacture or trade company?

We are manufacture,have 20 years' experiences in this field.

2) What kind machines we produce?

Our factory produce plastic pipes machines, plastic machine.

3) What kind payment we accept?

Payment term like T/T

4) How long we need to produce the machines?

According to different machine model and configuation, we need different time, like 40 days to 2 months.

5) Will the machine be delivered on time ?

Sure,we will deliver your machine up recieving the balance payment.

6) How about the machine quality?

Our machine quality is reliable.We select every parts on the machine strictly and production and installation is done by

professional workers.We test each production step for the best machine.

7) How about the price?

You know ,the goods counts the the price.We select the best machine raw material such as siemens electrics,schneider and ABB etc.We will provide you the best machine with best price.

8) How long is your machine’s guarantee time?

One year

9) What can you provide for after sale service?

We can send engineers to your factory for installation and training.also 24 hours on-line service for you.