-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

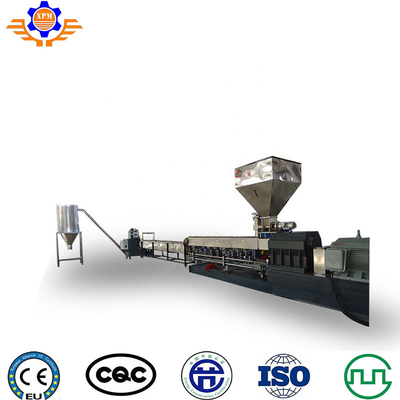

PP PE Film Granulating Line Waste Plastic Raw Material Recycling Pelletizing Machinery

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE/PP/PET/PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Granules |

| Output | 60-300Kg/H | Motor Power | 37Kw |

| Highlight | PVC Plastic Granules Machine,60Kg/H Plastic Granules Machine,300Kg/H plastic pelletizing recycling machine |

||

Newest PP PE Film Granulating Production Line Waste Plastic Raw Material Bags Recycling Pelletizing Machinery

Plastic Pelletizing and Granules Making Machine

QUICK DETAIL:

PP/PE Film Double Stage Pelletizing Recycle Line, Granulator PP/PE Double Stage Pelletizing Production Line double stage pelletizing extrusion line PP/PE Double Stage Granulating/Pelletizing Production Line PP/PE Two-stages pelletizing Line PP PE film pelletizing line Double rank pelletizing line pp pelletizing machine pe pp pelletizing machine pp pe granulating line

Description:

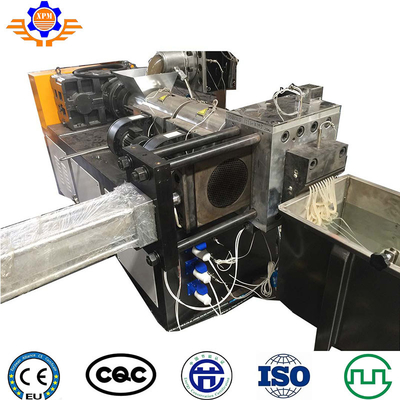

1. Plastic recycling granulator features: Different configuration, the use of special screw design and is suitable for the production of PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA, and other plastic regeneration and mixed color granules. Reducer adopts high torque design, realized the properties, such as no noise smooth operation. Screw, cylinder by the special hardening treatment, has wear-resisting, mixing performance is good, the characteristics of high production, the design of the vacuum exhaust or normal vent, to water in the process of production, waste gas discharged, the use of material is more stable, more solid, colloidal particles to ensure the product quality.

2.This machine is different from waste plastic machine, such as PP, PE, HDPE. especially resolved the problem of high-density polyethylene granulation broken bars.Double step plastic granulator is matched with plastic crusher and granular cutting machine. While the waste plastic materials through crushing and washing, could be put into extruder without drying. But the die head of machine could be electric screen changer or hydraulic screen changer. Simple process, advanced technology, automatic temperature control, national energy-saving patented heater, low power consumption, non-pollution, high degree of automation.

![]()

Applications:

1. special exhaust equipment

2. it can wipe off the liquid water content effectively , high output.

3. Pelletizing line using water ring pelletizer, granules are uniform and beautiful

Specifications:

| Item | Description |

| 1 | Inspection belt conveyer with iron absorber |

| 2 | Belt conveyer |

| 3 | Label removing machine |

| 4 | Belt conveyer |

| 5 | Crusher |

| 6 | Screw conveyer |

| 7 | Flotation tank |

| 8 | Screw conveyer |

| 9 | Hot washing tank ( with electric heating ) |

| 10 | Screw conveyer |

| 11 | High speed Scrubbing washing unit |

| 12 | Flotation rinsing unit 01 |

| 13 | Flotation rinsing unit 02 |

| 14 | Centrifugal dryer |

| 15 | Vibrosieve ( powder dust separator ) |

| 16 | Electric heating drying unit |

| 17 | Small paper and label separator |

| 18 | Silo |

| 19 | Electric control cabinet |

Competitive Advantage:

1. High quality and reasonable price

2. 12 months guarantee period and after-sales service

3. we are factory , we can invite customer to visit our factory and test the machine