-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

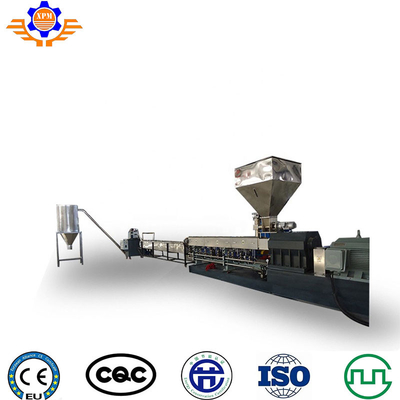

260 To 300kg/H Hdpe Granules Extruder Pet Granules Making Machine PP PE LDPE Film Recycling Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE/PP/PET/PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Granules |

| Output | 60-300Kg/H | Motor Power | 37Kw |

| Highlight | 260kg/h hdpe granules extruder,300kg/h hdpe granules extruder,pet granules making machine ODM |

||

PP PE Plastic Granules Machine , PP PE Film Recycling Granulating Equipment , HDPE LDPE Film Granules Making Machine

Quick detail:

1. The equipment is mainly for all kinds of agricultural film, packaging film, life film, as well as low density LDPE and high density HDPE and PET film crushing cleaning and granulation.

2. For recycling the waste plastic, such as waste PET bottles, PP PE film, woven bags, nylon, bottle flakes, shred lumps, pipe flakes, we should use two recycling steps, first one is crushing washing drying, after washing recycling line, we can get clean dry plastic scrap/flakes.

3. The second step is the pelletizing, we can feed the clean dry waste plastic scrap into the pelletizing line to get pellets, according to the different plastic type, the pelletizing machine is divided into water ring type pelletizing line and noodle strip pelletizing line, the feeding material type also have two different way, one is force feeding type which is suitable for hard material, another is compactor type pelletizing line, which is designed specially for soft material, like woven bags, nylon, film etc.

![]()

Features of plastic granulator machine:

1. The raw material is first sent to the crusher by the pre-cleaning machine through the conveyor uniformly PE film, broken into about 80 mm piece of material, flowing into the friction cleaning machine for the second cleaning. When the material through the friction cleaning machine after cleaning into the high temperature cooking pot, PE material oil impurities in the machine fully separated and into the separation of precipitation box, in the precipitation box under the action of the roller PE material constantly get rinsed.

2. At the same time, with the overflow of water, the net conveyor at the end of the precipitation box is sent to the centrifuge. After centrifugal dewatering, the material is sent to the pipe dryer through the fan, and then separated into the collecting bin through the cyclone, and then sent to the double-stage extrusion granulator through the flat belt system for extrusion and granulation.

3. Reducer adopts high torque design to achieve no noise and smooth operation.Screw, barrel by special hardening treatment, with wear resistance, good mixing performance, high yield characteristics.

4. The design of the exhaust port can discharge water and exhaust gas in the production process, so that the granules are more stable and the granules are stronger, ensuring the excellent quality of the products.The unit has the advantages of large output, high benefit, stable quality and easy operation, and is the best choice for plastic granulating manufacturers to develop new products.

![]()

Specification of Plastic bags and film recycling granulating machine:

| Model |

Screw Diameter (mm) |

Rotary Speed (rpm) |

Main motor(Kw) | Compacting Machine(Kw) | Output(kg/h) |

| JIN85-33 | 85 | 10-120 | 55 | 38 | 150-200 |

| JIN100-33 | 100 | 10-120 | 90 | 58 | 260-300 |

| JIN130-33 | 130 | 10-120 | 130 | 77 | 330-400 |

| JIN160-33 | 160 | 10-120 | 162 | 91 | 520-600 |

| JIN180-33 | 180 | 10-120 | 240 | 135 | 880-1000 |

![]()

Competitive Advantage:

large output, high benefit, stable quality and easy operation

Machine display:

![]()

![]()