-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

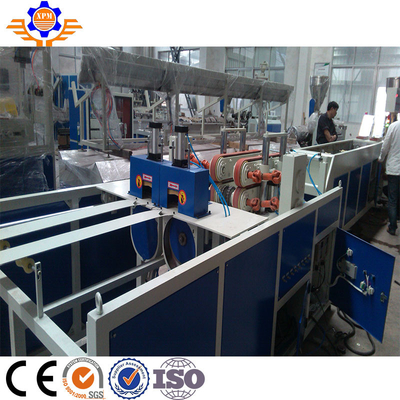

Electrical PVC Conduit Pipe Making Machine , High Speed Pipe Manufacturing Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 450Kg/H | Motor Power | 55Kw |

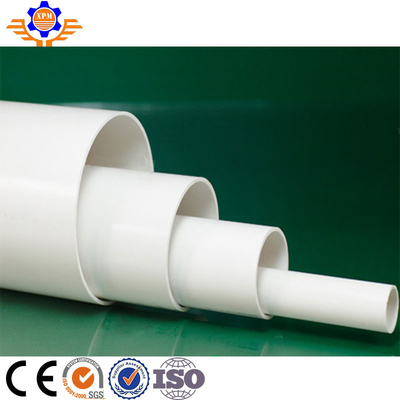

PVC ELECTRICAL CONDUIT TWO TUBE MAKING MACHINE DIAMETER 16-50MM

COMPONENTS AND FEATURES:

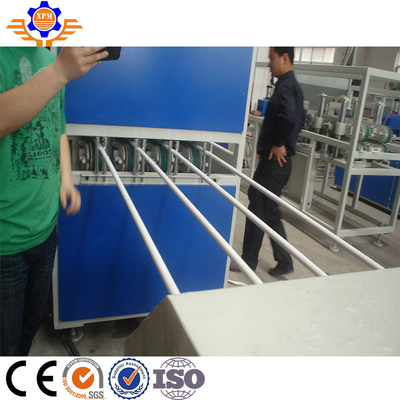

PVC double strands electrical conduit pipe extrusion line is applied for manufacturing PVC electrical conduit pipe with the pipe diameter of 16-32mm, 16-50mm and different pressure classes that is applied in fields of building, architecture, telecom communication, etc..

Covering a large range of diameters, we supply vacuum calibration sleeves which are used inside the vacuum tanks for the calibration process.

Features

High wear resistant

Definite outer diameter calibration

Product Range

We provide vacuum tanks for the calibration and cooling process of plastic pipes covering diameters from 16 to 800 mm. All of our tanks are built in stainless steel which guarantees total absence of corrosion. Motorized longitudinal movement lets precise and fast positioning during the process.

Stainless steel tank

Motor driven longitudinal movement

Product Range

Diameters from 16 to 800 mm

Vacuum tank length from 6 to 9 mt

Cooling tanks are manufactured from SUS304 stainless steel. Seals at inlet and oulet of tanks has been developed ase brush seal istead of rubber seals This development let to change diameter more quickly. The pipe support in tanks are roller type supports.

A wide range of haul-off units allows us to supply to the customers the ideal solution for a diameter range of 16 to 800 mm. We supply both caterpillar and belt-type haul-off units on our pipe down streams.

Caterpillar is driven by AC or servo drive

Synchronization with extruder speed

Speed adjustment by inverter

Product Range

Caterpillar tracks from 2 to 8

Several types of cutting units for pipe applications. For medium and large diameter pipes, we supply our planetary cutting units. For small diameter pipes, we offer our guillotine and saw cutter.

Planetary Cutter:

Cutting and chamfering rigid pipes

Synchronization with extruder speed

Low maintenance cost

Adjustable cutting speed

Product Range: Pipe range from 50 to 800 mm

Saw Cutter:

Cutting pipes up to 63 mm

Low maintenance cost

Adjustable cutting speed

Cutting pipes up to 63 mm

Pipe range from 16 to 63 mm

Guillotine Cutter: GK 32 Features

Special design for pipes

Dust and chip-free cutting system

Low maintenance cost

Special designing of this machine with the necessary adaption of tools PP and PVC wasted water and sewage pipes bas been made possible. The fully automatic machine that is running in line.

With the special design of this machine is very high capacity production is possible. It can also produce 150cm pipe. also depending on customer requests we also manufacture special manual belling machine

The belling machine is capable of belling PE,PP,PVC pipes and sizes can be specified in international standards.

By working synchronous with pipeline, without any human intervention machine can take pipes from the line then make belling.

Pipe heating degree and blowing pressure can be adjusted.

With the wide selection feature on touch screen, wastage of pipe can be prevented.

By using internal PLC system, machine can work independently from pipe line.

XPM-32 is the model that has the highest capacity. For this model, the diameter range of 16-32mm, it is designed to produce 4 sockets per cycle.

XPM-63 is the model that has the highest capacity as well. For this model, the diameter range of 16-63mm, it is designed to produce 2 sockets per cycle.

The complete extrusion consists of following items:

- Conical Twin Screw Extruder:

It is used for melting and stirring plastic material. We adapts special screw and barrel type that provide perfect mixing and homogenous.

We use special gear box for the Extruder which has axial bearings. Transfer the motor to the screw. For minimizing electricity consumption, we use the famous brand of driving motor of “SIEMENS” on our Extruder. Automation system designed with PLC and touch panel controller can be selected.

- TWO Strands Die-Head:

The die head and die system is manufactured with melt flow channels designed to ensure excellent performance in whole range of pipe diameter. According to the material characteristic of pipe, the designing of the die head and die system changes and even at high extrusion pressure. It gives perfect outcome.

- TWO Strand Vacuum Tank:

The Vacuum Tanks are manufactured with stainless steel.

Our nozzles designing for maximum cooling performance. Cooled water sprinkles to hot plastic pipe outside face from the nozzles.

With high power water pump, cooled water can reach to pipe completely.

Our vacuum tank’s pressure can be adjusted, so vacuum pressure can be fixed according to pipe requirement. We sealing gasket for every lid on the vacuum tank. This stops vacuum leakage and minimizing energy consumption.

![]()

- TWO Strands Belt Type Haul-offs:

The belt haul-off is used for high speed extrusion of small pipe. it is free from vibration and ensure the excellent control even at high speed.

With the material we have used in our haul-offs, we have very good adhesion to the pipe and ensure slip prevented.

The needed speed for setting of belts can be changed with electrical inverter. Different line speeds are adjusted by using control panel easily.

- TWO Strands Saw Cutter:

Automatic cutting unit, that is ideal solution for small and medium size pipes. It works synchronic with belt haul-off.

Pipe length to be cut is easily adjusted via the touch screen.

Pipe length measure by encode so desired length can cut precisely.

- TWO Strands Tipping Table:

- It operates on pneumatic cylinder.

SPECIFICATIONS:

| MODEL | PIPE DIAMETER (MM) | EXTRUDER MODEL | MOTOR POWER (KW) |

| XPM-32F | 16-32 (FOUR PIPE) | SJSZ65/132 | 37 AC |

| XPM-32E | 16-32 (DOUBLE PIPE) | SJSZ51/105 | 22 AC |

| XPM-32W | 16-32 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| XPM-40E | 16-40 (DOUBLE PIPE) | SJSZ51/105 | 22 AC |

| XPM-40W | 16-40 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| XPM-50E | 16-50 (DOUBLE PIPE) | SJSZ51/105 | 22 AC |

| XPM-50W | 16-50 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| XPM-63W | 16-63 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

![]()