-

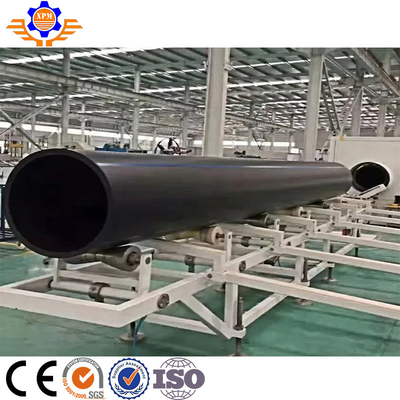

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

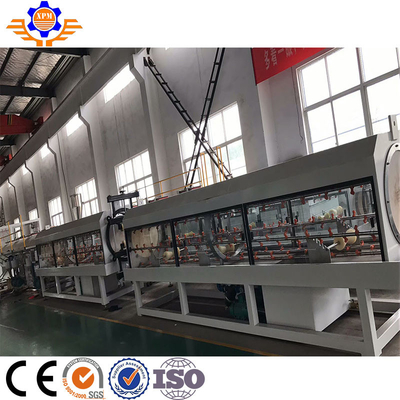

20-63MM 6KW HDPE PP Pipe Extrusion Line Plastic Pipe Making Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150Kg/H | Motor Power | 55Kw |

| High Light | 6KW HDPE PP Pipe Extrusion Line,150KG/H PP Pipe Extrusion Line,plastic pipe making machine 150Kg/H |

||

20-63MM 6KW HDPE PP Pipe Extrusion Line Plastic Pipe Making Machine

Description:

PE pipe extrusion lines are applied for manufacturing PE pipes with different pressure classes needed in field of petrol gas, agriculture, architecture, telecom communication, etc..

Machine Parameter:

example Extruder: SJ30

| No | Model | Details |

| 1 | Hopper Dryer |

· Material: Stainless Steel Heating Power: 6KW · Fan Power: 0.37KW · Hopper Volume: 150KG/H

|

| 2 | SJ30 Single Screw Plastic Extruder |

· Screw Diameter:¢30mm · The ratio of L/D: 28:1 · Screw Maximum Rotating Speed: 15-150Rpm · Motor Power: 7.5KW · Screw and Barrel Material: 38CrMoAlA Nitrogen Treatment · Depth of Nitrogen Treatment: 0.4-0.7 · Screw Straightness: <0.015 mm · The hardness of Screw: HV800-1000 · Heating Method: Casting Aluminum Heater · Heating Zones: 4Periods(Screw Barrel 3periods, Head Piece 1 Periods) · Heating Power:12KW · Cooling Method: Forced Air Cool · Cooling Zones :3 periods · Fan Motor Power : 180W*3= 0.54KW · Electrical System: ABB Frequency Converter · Temperature Control Meter: RKC · Gear Box: Hard Tooth Face · Central Height: 1000mm · Size : 1500*1090*2127mm · Weight: 400kg |

| 3 | Mold and Head |

· Mold Material: Steel 40Cr · Mold Size for OD10mm, ID 8.5mm tube Connection head material: 45# carton steel

|

| 4 | Vacuum and Water cooling tank |

· Vacuum forming part : Length: 2m · Vacuum pump power: 2.2kw · Material: stainless steel · Heating device for good quality pipe forming · Water cooling tank parts : · Length: 1m · Material: stainless steel · Machine structure material: Q235 steel · (height and direction adjustable) · Size : 3000*1120*310

|

| 5 | Haul off with a cutting device |

· Haul off speed: 1-15m/min or required · Driving motor: 0.55kw*2 · Cutter motor type: servo motor · Motor power: 1.5kw · Cutter blade material: high-quality tooling steel · Final tube cutting length could be adjusted · Cutting tube number could be seen in the PLC system · Control system ( PLC control system ) · Size : 1500*900*850

|

![]()

OUR SERVICE:

Pre-sales service:

- Introducing in detail features and application of the products to customer

- Selecting economical and practical machine & equipment for customer

- Providing operation data of the related machine & equipment

- Providing means of trial performance for customer

Sales service:

- Recommending engineering conditions required for installation of the machine & equipment

- Communicating in time the manufacturing progress of the machine with the user

- Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-sales service:

- Providing on-the-spot technical assistance in installation, commission and training

- Filling in detail customer’s information

- Providing long-term maintenance service and spare parts

- Giving technical support to customer for developing new product

- Providing free maintenance for a year

![]()

Q&A:

Q: Are you a trading company or manufacturer?

A: We are a manufacturing factory with several years of experience.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 45-60 days if the goods are not in stock, it is according to what kind of machine you need

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample free of charge but do not pay the cost of freight.

Q: What are your terms of payment?

A: 30% T/T in advance,70% balance before shipment or Negotiable

If you have another question, please feel free to contact us as below