-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

Gas Water 4 To 9m/Min PE Pipe Extrusion Line Single Screw Compounding Extruder

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150Kg/H | Motor Power | 55Kw |

| High Light | 4m/Min PE Pipe Extrusion Line,9m/Min PE Pipe Extrusion Line,220V twin screw compounding extruder |

||

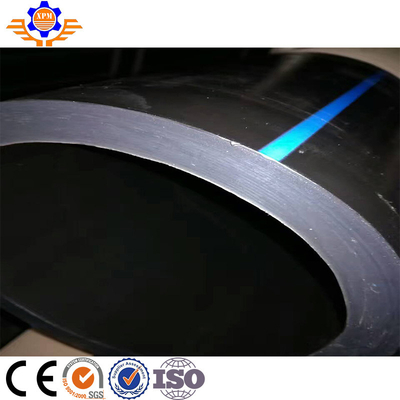

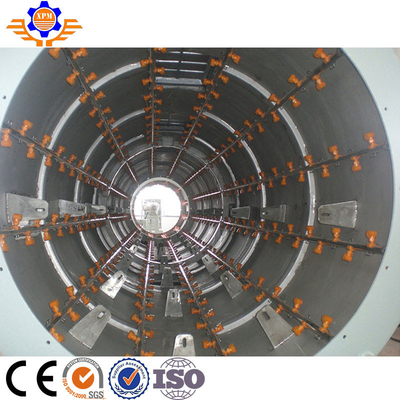

PE Pipe Extrusion Line HDPE gas water pipe machine, PE gas pipe extrusion line

- Specially-designed spiral moulds for PE pipes, with inside oil controlling temperature system. plastic machine

- Extruder adopts big L/D and multi mixing structure, which is more suitable for the PE low temperature extrusion production.

PE PIPE PROCUTION LINE MAIN COMPONENTS:

| No | Equipment | Quantity |

| 1 | Vacuum loader and hopper dryer | 1set |

| 2 | Single screw extruder | 1set |

| 3 | Die-head | 1set |

| 4 | color line extrusion extruder | 1set |

| 5 | Vacuum calibration & cooling tank | 1 set |

| 6 | Hauling machine | 1set |

| 7 | Cutting machine | 1set |

| 8 | Pipe stacker | 1set |

| 9 | Electric control cabinet | 1set |

| Auxiliary machines for your choice | ||

| 10 | Printer | 1set |

| 11 | Mixer | 1set |

| 12 | Crusher | 1set |

| 13 | Pipe winding machine | 1 set |

| 14 | Milling machine | 1set |

![]()

PE pipe extrusion line

| Model | Pipe specification(mm) | Extruder | Max capacity(kg/h) | Total Power(kw) |

| XPM-110 | 20-63 | SJ60/33 SJ25/25 | 120-220 | 130 |

| XPM-160 | 50-160 | SJ60/33 SJ25/25 | 120-220 | 130 |

| XPM-250 | 110-250 | SJ75/33 SJ25/25 | 280-350 | 280 |

| XPM-450 | 160-450 | SJ90/33 SJ25/25 | 350-500 | 400 |

| XPM-630 | 315-630 | SJ120/33 SJ25/25 | 550-980 | 550 |

| XPM-800 | 400-800 | SJ150/33 SJ25/25 | 800-1400 | 750 |

| XPM-1600 | 800-1600 | SJ150/33 SJ25/25 | 800-1400 |

1200

|

COMPONENTS AND FEATURES:

Saijia Extrusion operates in the manufacturing of plastic extrusion machines and systems for over many years. Saijia Extrusion is the reliable solution partner from planning and process engineering for the optimum solution through set-up, start-up and operation of extrusion systems.

Applications include plastic profile, pipe and pelletizing extruders or complete extrusion lines. All machines and lines are tailor-made according to the customer’s demands and needs.

We always aim to provide high performance extruders and energy efficient systems as well as reliable and fast spare parts delivery, service and support.

All Extrusion pipe lines can be equipped with various auxiliary equipments in order to meet our customer’s requests and provide solution from a single source.

![]()

Saijia MACHINERY is a company that makes manufacturing of PE/PP-R pipe machinery. Company principles are manufacturing without compromising high quality and standards and being customers oriented.

Applications include plastic profile, pipe and pelletizing extruders or complete extrusion lines. All machines and lines are tailor-made according to the customer’s demands and needs.

We always aim to provide high performance extruders and energy efficient systems as well as reliable and fast spare parts delivery, service and support.

All Extrusion pipe lines can be equipped with various auxiliary equipments in order to meet our customer’s requests and provide solution from a single source.