-

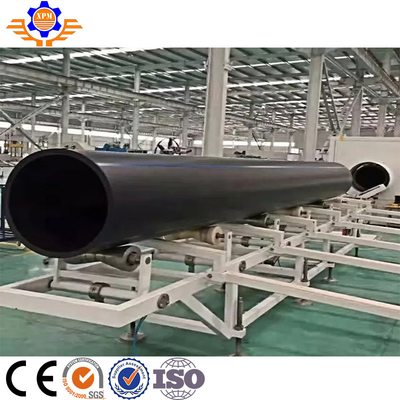

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

20-63MM PPR ABS HDPE PE Pipe Extrusion Line Plastic Pipe Production Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150Kg/H | Motor Power | 55Kw |

| High Light | PPR ABS PE Pipe Extrusion Line,HDPE PE Pipe Extrusion Line,150Kg/H Plastic Pipe Production Line |

||

20-63MM PPR ABS HDPE PE Pipe Extrusion Line Plastic Pipe Production Line

The Single Screw Extruder is designed for PE and PP pipe applications.We target to provide the optimal solutions for the customer’s special needs with the advantage of flexibility in material choices, high performance and long durability.

High flexibility in raw material combinations

Gentle and homogeneous plastification

Different screw geometries for customer’s special needs

Barrel with air cooling system

AC motors for low energy consumption

Control panel with color touch screen

Product Range

Screw diameters from 45 to 160 mm

L/D ratios from 30:1 to 36:1

Outputs from 85 to 1650 kg/h

All Extrusion pipelines can be equipped with various auxiliary equipment in order to meet our customer’s requests and provide solution from a single source.

![]()

Covering a large range of diameters, we supply vacuum calibration sleeves which are used inside the vacuum tanks for the calibration process.

Features

High wear-resistant

Definite outer diameter calibration

Product Range Diameters from 16 to 800 mm

![]()

Application:

This machine is mainly used to process PP, PE,PPR and other plastic materials equipped with auxiliary machines, it can manufacture profile, pipes, wire and other plastic products and granulation. it has the advantage of simple production technological process, high output, stable quality and low cost.

Features:

SJ series extruder is composed of barrel screw, gear transmission system,measurable feeding, vacuum gasing, heating, cooling and electronic control components, etc.

The screw is made by high precision special digital screw miller, extruding property can be highly harmonized.

It has firstly introduced the advanced technique of producing screws with variable pitch and depth so that the material can be more softly sheared and cut.

The distribution box is specially designed, pull force bearing is fully imported, the drive life span can be prolonged. It can bear larger extruding pressure.

The involute gear driving is characterized by low noise, stability in working , big bearing capacity, and long service life.

This machine is advanced in design, high in output, good in plasticization and low in energy consumption.

Technical Data:

| Product Name | Screw diameter (mm) | L/D | Motor power kW |

Screw speed (r/min) |

Max output (kg/h) |

| SJ25/25 | 25 | 25:1 | 1.5 | 100 | 3.4 |

| SJ30/25 | 30 | 25:1 | 5.5 | 125 | 12.5 |

| SJ45/25 | 45 | 25:1 | 7.5 | 100 | 20 |

| SJ45/30 | 45 | 30:1 | 15 | 145 | 40 |

| SJ45/30 | 45 | 30:1 | 30 | 185 | 120 |

| SJ65/25 | 65 | 25:1 | 22 | 100 | 60 |

| SJ65/30 | 65 | 30:1 | 30 | 105 | 80 |

| SJ65/30 | 65 | 30:1 | 45 | 120 | 120 |

| SJ75/30 | 75 | 30:1 | 90 | 120 | 350 |

| SJ90/25 | 90 | 25:1 | 55 | 120 | 150 |

| SJ90/30 | 90 | 30:1 | 90 | 94 | 250 |

| SJ120/25 | 120 | 25:1 | 90 | 94 | 350 |

| SJ120/30 | 120 | 30:1 | 110 | 94 | 350 |

| SJ120/33 | 120 | 33:1 | 250 | 94 | 800 |

| SJ150/30 | 150 | 30:1 | 132 | 50 | 350 |

Our Advantages:

l High quality

l Reliable, Durable

l Reasonable and competitive price

l Good after-sale service & within 12hours replying by email

l One year guarantee

![]()

Our Services:

Engineers available to service machinery overseas.

Warranty: One year after B/L date.

If the equipment fails due to the quality of the machine for one year, we will provide replacement and the repair Free of Charge. After One Year customer must pay for Spare Parts, we will provide long-term technical assistance.

Workers must operate the machines according to the design of the machine. Saijia Machinery will not be responsible for accidents which are caused by improper operation of workers.