-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

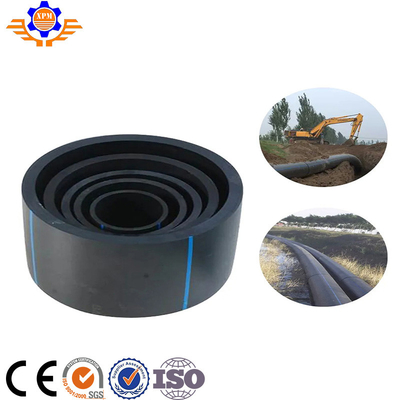

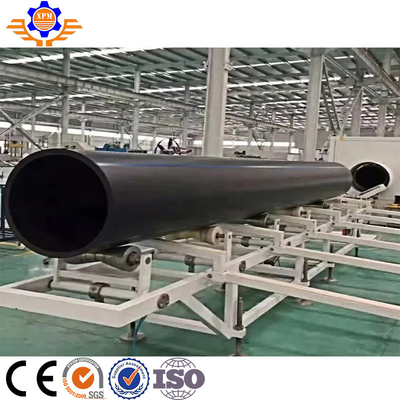

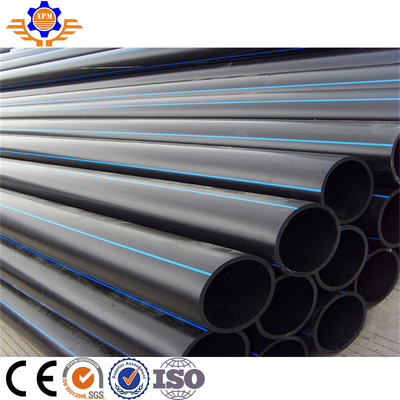

63-110MM PE Pipe Extrusion Line Hdpe Pipe Extruder Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 250Kg/H | Motor Power | 90Kw |

| High Light | 110mm PE Pipe Extrusion Line,315mm PE Pipe Extrusion Line,250KG/H hdpe pipe extruder machine |

||

63-110MM PE Pipe Extrusion Line Hdpe Pipe Extruder Machine

1. High Speed Pe pipe extrusion Line introduction;

PP-R PE-RT PB pipes are widely used in the uptown apartment and village cables protection hot water supplying house heating. This production line adopts high efficiency single screw extruder equipped with the Siemens PLC controlling system. It can ensure the whole line automatic controlling of high capacity stable extruding with the suitable changing of different units could realize the production job of PP-R PE-RT PB pipe.

![]()

Advantages of high speed PE pipe extrusion line are as following:

It’s for high speed extruding PE PPH PPR PPB PERT and PB etc line speed is up to 30m/min.

L/D=38 double mixer and barrier screw which can ensure 100% plasticization before going into die with spiral groove on feeding part it increases 30% of productivity.

Die with spiral mandrel it ensures no delay in the flow channel which can improve pipe quality.

Particular disc design on calibration sleeves which ensures high speed extrusion.

Double-strand vacuum tank is controlled individually which makes convenient operation as single one.

Double haul-off is also controlled individually which makes convenient operation as single strand additionally with the upper caterpillar belt stop device to ensure roundness of pipe.

With individual designed of chipless cutter. Driven by motor and synchronous belts which ensures normal cutting during high speed running.

![]()

High speed PE pipe extrusion line from Saijia MACHINERY :

The high speed PE pipe Extrusion line is Saijia MACHINERY company developed a new type of pipe production line for PE , pp jing and other polyolefin pipe in high extrusion speed , all models with advanced PLC/PCC modular intelligent control system , in order to realize the whole production line automation and real-time data recording and closed-loop control ,

the production line has some high yield , wide adaptation of raw materials , suatained and stable production of high quality productions such as columns a bit .

High speed PE pipe extrusion line technical parameters:

| SPECIFICATIONS FOR HIGH SPEES PE PIPE EXTRUSION LINE | ||||

| Model | Pipe spec(mm) | extruder | Max.output (kg/h) |

Total power(kw) |

| XPM63-PE | Φ20-Φ63 | SJ65/38 | 250-300 | 75 |

| XPM110-PE | Φ63-Φ110 | SJ65/38 | 250-350 | 90 |

| XPM250-PE | Φ75-Φ250 | SJ75/38 | 500-550 | 185 |

| XPM450-PE | Φ160-Φ450 | SJ90/38 | 700-750 | 250 |

| XPM630-PE | Φ315-Φ630 | SJ120/38 | 900-1100 | 280 |

| XPM800-PE | Φ400-Φ800 | SJ150/35 | 1000-1200 | 315 |

| XPM1000-PE | Φ630-Φ1000 | SJ150/38 | 1000-1200 | 315 |

| XPM1200-PE | Φ800-Φ1200 | SJ120/33 & SJ90/38 | 1500-1700 | 280/220 |

![]()

![]()