-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

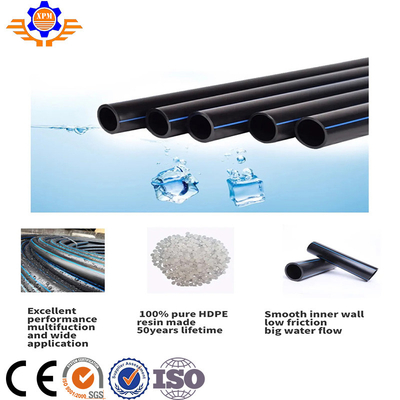

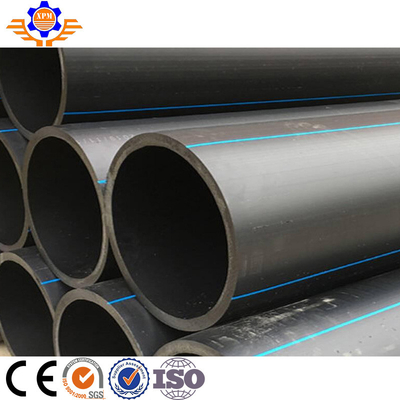

20-110MM PE Pipe Extrusion Line Different Pressure Classes Needed In Field Telecom Communication

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 150Kg/H | Motor Power | 55Kw |

| High Light | 150kg/hr PE Pipe Extrusion Line,PE Pipe Extrusion Line 55Kw,hepe pp plastic extruder machine |

||

20-110MM PE Pipe Extrusion Line Different Pressure Classes Needed In Field Telecom Communication

Application:

PE pipe extrusion lines are applied for manufacturing PE pipes with different pressure classes needed in field of petrol gas, agriculture, architecture, telecom communication, etc..

Equipment:

Single screw extruder is the professional equipment to extrude the material of polyethylene. Equipped with different die head, downstream equipment, it can be applied for manufacturing of polyolefin pipe, panel, sheet, film, yarn and pelletizing, etc.. It consists of following items:

- Driving motor: equipped with famous brand motor as driving source.

- Gearbox: equipped with famous brand gearbox to ensure the maximum output of power

- Screw & barrel: both the screw and barrel adapted the designing of combined of independent teeth and mixing components together for screw and the feeding groove and longer feeding section together for barrel

to get the optimizing plasticizing and capacity. - Control system: equipped with famous brand electrical components ensure to get the accurate control

![]()

Specification:

| MODEL | Pipe diameter(mm) | Extruder | Extruder power(kw) | Capacity(kg/hr) |

| XPM-63 | 20-63 | SJ65/33 | 55AC | 150 |

| XPM-110 | 20-110 | SJ65/33 | 55AC | 150 |

| XPM-160 | 75-160 | SJ75/33 | 90AC | 280 |

| XPM-250 | 90-250 | SJ75/33 | 110DC | 350 |

| XPM-315 | 110-315 | SJ90/33 | 160DC | 450 |

| XPM-450 | 160-450 | SJ90/33 | 160DC | 450 |

| XPM-630 | 315-630 | SJ120/33 | 280DC | 850 |

| XPM-800 | 500-800 | SJ150/33 | 315DC | 1100 |

| XPM-1200 | 710-1200 | SJ150/34 | 400DC | 1350 |

![]()