-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

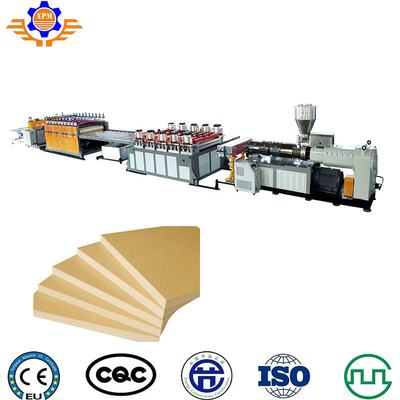

450kg/Hr 240kw PVC Board Making Machine Extrusion Line Conical Double Screw Extruder SGS

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC,WPC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Decorative Materials |

| Output | 150-320Kg/H | Motor Power | 37Kw |

| Highlight | 450kg/hr PVC Board Making Machine,240kw PVC Board Making Machine,conical double screw extruder SGS |

||

PVC Foam Board Making Machine , PVC Foam Board Extrusion Line , Foam Extrusion Machine

Description of pvc foam board making machine:

1. The PVC foam board extrusion production line of SaiJia adopts the latest manufacturing technology.

2. PVC foam sheet/board is becoming the substitution of wood in many fields such as furniture, AD , Decoration and construction etc. and be accepted by more and more people now.

3. The main material is PVC. The raw material is PVC or PVC and wood mixing extrusion foaming process.

4. It covers not only features of wood, but also has its own features.It can be used for washroom cabinet, kitchen cabinet, door panel, door frame, wall cladding advertising material etc .

5. Equipment list

| 1 | SJSZ-80/173 conical twin-screw extruder | One set |

| 2 | Extrusion mold | One set |

| 3 | Hydraulic pressure calibration machine | One set |

| 4 | Cooling conveyor Bridge | One set |

| 5 | Edge cutting unit | One set |

| 6 | Rollers Haul-off | One set |

| 7 | Transverse cutter | One set |

| 8 | Stacking table | One set |

Technical Parameter:

| Thickness | 2-30mm adjustable |

| Width | 1220mm |

| Length | 2440mm |

| Material | WPC+ additive |

| Power supply | Three-phase, 380V, 50HZ ( as per customers' city power condition) |

| Capacity | About 400-450kg/hr |

| Install power | 240kw |

| Operation worker | 2-3workers/shift |

| Warranty time | 12monthes |

| Dimension | 30*5*3.5M |

| Weight | 25T |

| Container | Two 40Containers |

| Certificate | ISO9001:2008&CE&SGS |

Application:

1) Ceiling of car and train carriage etc.

2) Internal decoration and external building wall. Office, living house decoration.

3) Exhibition desk, Shelve in supermarke

4) Architectural decoration and upholstery

5) Decoration for partition wall and shop windows

Competitive advantages:

This PVC Skinning Foam board production line has low output as well as low power consumption, but it is easier tooperate and needs less maintenance after long time running.