-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

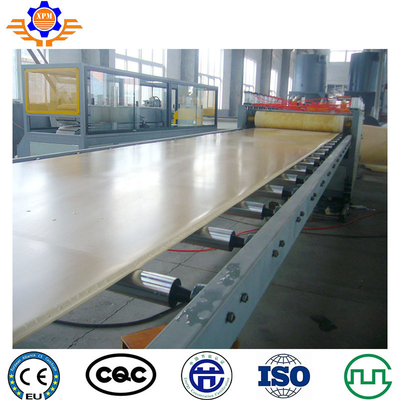

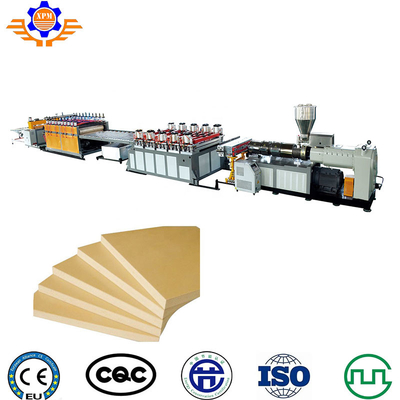

320Kg/H Pvc Foam Board Making Machine Ceiling Panel Production Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC,WPC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Decorative Materials |

| Output | 150-320Kg/H | Motor Power | 37Kw |

| High Light | 320Kg/H pvc foam board making machine,350Kg/H pvc foam board making machine,Automatic pvc ceiling panel making machine |

||

PVC Foaming Board Making Machine Line With Factory Price , PVC Furniture Board Production Line

Quick detail:

Main Features of PVC/WPC Foam Plate/ Board/Sheet Production Line

1. Wood-plastic mould ,resembling wood in appearance,is more fixed in size than wood without cracks,curls,protu berances,and cross grains,it has the features of better physical and chemical property,to ensure higher density and longer service life.

2. Wood-plastic mould can be reproduced like wood.It can be cut,planed,madea bond by glue or fastened with nalis or screws.It's easy to maintain.

3. Preserved from acid,alkali,corrosion,impervious to attacks by insects and rats,wood-plastic mould plates provide less moisture absorption.

4. The product can be recycled and degraded for environmental protection

Description:

High Quality PVC Foam Board Making Machine

1.This Machine can produce pvc products of different specifications only via changing mould.

2.Pvc board machine also include the die head, cooling calibrating mould, cooling carrying roller,hauling-off unit, edge trimming device,dust collecting machine,cutting device,and delivery stacker.

3.All the eletrical parts in line are from famous brand supplier,SIEMENS &ABB brand,insure the machine can high stable running.The machine also have the features of high automatic,easy operate etc.

Main components of this machine:

1. SJSZ80/156 conical twin screw extruder

2. Die mould

3. Calibrating table

4. Haul-off machine

5. Automatic cutting machine

6. Length treaturement

7. Tilting table

![]()

Main tech parameters of PVC foam board making machine

Technical parameters:

| PVC/WPC Foam Plate/ Board/Sheet Production Line | |||

| Model | SXJZ1220-A | SXJZ1220-B | SXJZ1500-C |

| Extruer | SJSZ80/156 | SJSZ80/173 | SJSZ92/188 |

| Max.output(kg/h) | 350 | 600 | 650 |

| Die width(mm) | 1320 | 1320 | 1550 |

| Production width(mm) | 1220 | 1220 | 1400 |

| Power(kw) | 146 | 170 | 205 |

Applications of Board Making Machine:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anticorrosion project, special cold project, environmental protection.

Competitive Advantage:

Our Service:

1) We give you suitable suggestions according to your actual need.

2) Technical support: available lifelong

3) Under the right operation way, the screw and barrel is for 10000 working hours.

4) Our expert will answer any inquiry within 48 hours and it will be solved as soon as possible.

5) The customer can send the engineer to our company with training

6) Our engineer can be to the Buyer's company for installation and testing the lines.

7) The seller provides you with complete technical support documents and the relative drawings of the electric components written in Chinese and English.

![]()