-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

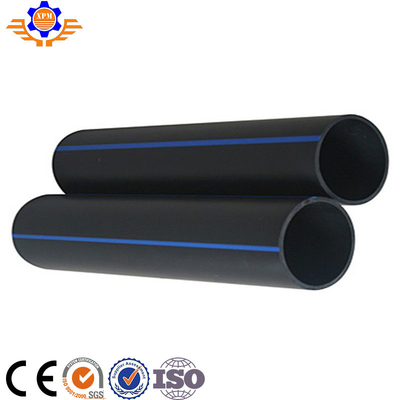

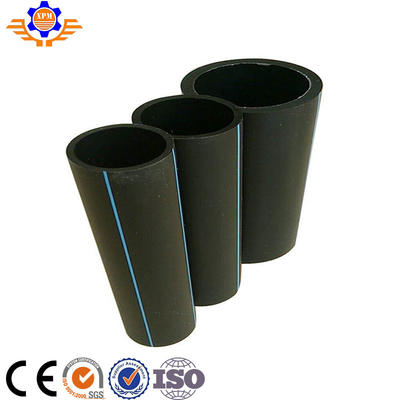

63 - 250MM Single Screw HDPE PE Pipe Extrusion Line PPR Pipe Making Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PE,PP,HDPE |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 250Kg/H | Motor Power | 75Kw |

| High Light | PPR Pipe Making Machine 250mm,HDPE Pipe Single Screw Extruder,Single Screw PE Pipe Making Machine |

||

63-250MM Single Screw HDPE PE Pipe Extrusion Line PPR Pipe Making Machine

Features:

• First class pipe die was designed with many years experience

• Perfect twin pipe vacuum sizing system;

• Controlled independently unitary structure twin pipe hauling mechanism and synchronous cutting device;

• Optional length set and accurate adaption stacker.

Consist For Full Production Line:

A. Single screw extruder

B. PPR/PE/PP pipe extrusion mould

C. Vacuum shaping platform

D. Haul off machine

E. Cutting machine

F. Stacker

After-sale service& Technology support:

• To install products and test products freely for customers.

• To provide the formulas and technologies of relevant products and the information of chemical

materials manufactories.

• To direct technology aspect of relevant use according to customers’ requirements

• To provide technical training for clients’ employees.

• To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Main technical parameter:

| type | pipe range(mm) | Max. output(kg/h) | total power(kw) | L*W*H(m) |

| PE-250 | 110-250 | 350 | 230 | 44*2.5*3 |

| PE-400 | 160-400 | 600 | 400 | 45*3*3.5 |

| PE-630 | 315-630 | 800 | 490 | 56*3*3.5 |

| PE-800 | 500-800 | 1000 | 650 | 58*3.5*3.5 |

| PE-1000 | 630-1000 | 1200 | 760 | 62*3.5*3.5 |

| PE-1400 | 800-1400 | 1500 | 820 | 67*4*4 |

![]()

![]()