-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

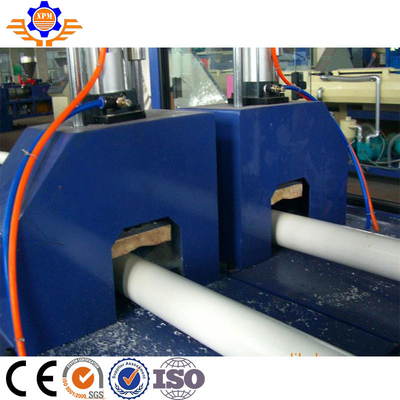

U-PVC C-PVC PVC Pipe Extrusion Line Plastic Pipe Making Machines

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Plastic Pipe |

| Output | 250Kg/H | Motor Power | 37Kw |

| High Light | UPVC Plastic Pipe Making Machines,CPVC Pipe Extrusion Line,37Kw PVC Pipe Extrusion Line |

||

U-PVC C-PVC PVC Pipe Extrusion Line Plastic Pipe Making Machines

Components:

1. extruder: adopting conical twin-screw extruder, uniquely designed screw, realizing the shorting plasticizing time good compounding and excellent plasticization.

2. gearbox: adopting perfect quality gearbox, with a nice outline, stable running, low noise, and long service time.

3. extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature control.

4. screw and barrel: screw-core installing with internal temperature controlling system, barrel equipped with

vacuum degassing system can get rid of the waste gas from the raw material which can guarantee super quality of the products.

5. driving system: adopting A.C motor, using FUJI or ABB inverters which provide stable torque output and various speeds.

6. vacuum calibrating tank: with two vacuum chambers which can make sure the perfect roundness of the

pipe, spraying water cooling, equipped with a temperature controller, realizing automatic discharging the water, the main body of the tank make of stainless steel, long service time.

7. haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws, and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter.

8. cutting unit: saw cutting and planet saw cutting, with a dust collection system.

9. staking unit: automatic overturning system, can freely fix the length of the pipe.

10. controlling system: manual controlling cabinet or SIEMENS PLC touch screen control.

![]()

SPECIFICATIONS:

| Model | Screw diameter(mm) | Rotary speed (rpm) | Motor power (kw) | Capacity (kg/hr) |

| SJZ45/90 | 45/90 | 45/34.7 | 15 AC | 100 |

| SJZ51/105 | 51/105 | 45/34.7 | 18.5 AC | 150 |

| SJZ55/110 | 55/110 | 45/34.7 | 22 AC | 200 |

| SJZ65/132 | 65/132 | 45/34.7 | 30/37 AC | 250 |

| SJZ80/156 | 80/156 | 34.7/25 | 55 AC | 350 |

| SJZ92/188 | 92/188 | 34.7/25 | 110 DC | 800 |

Our Service:

1. We provide a basic formula to our customers for each project. And our engineers will help customers to do formula

adjustments according to requirements.

2. Our engineer will help customers to install the machines in the Customer’s factory.

3. We provide machine operation and maintenance training for our customers.

4.We provide machine operation and maintenance training for our customers.

![]()

![]()