-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

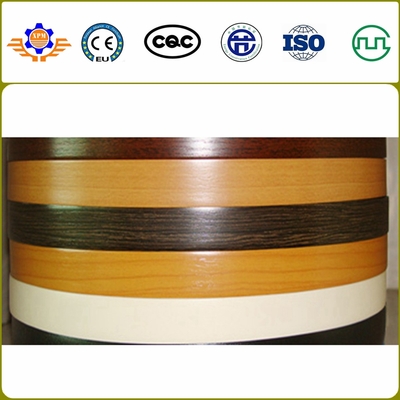

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

-

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company!

JamesThe carpet backing extrusion machine is good quality , it is beautiful and the output is stable , this is a reliable company! -

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line!

ShrifThis is a professional manufacturer! I am satisfied with your pvc pipe line! -

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

SofiaThis pvc edge banding line is very good , and the after-saes service is good. The machine is easy to operate and the output is stable!

Double Output PVC Edge Banding Machine | Furniture Edge Banding Making Machine | Siemens Motor

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 380V Or Customized | Application | Decorative Materials |

| Output | 80-150Kg/H | Motor Power | 18.5kw |

| High Light | Furniture PVC Edge Banding Making Machine,Double Output PVC Edge Banding Machine,150Kg/H PVC Edge Banding Production Line |

||

【 PVC edge banding making machine 】or 【 PVC edge banding extrusion line 】is one of our advantage products , XPM company has focused on plastic machinery over 20 years with rich experience and strong technology , our machinery has exported to over 25 countries , like Italy, Poland , Turkey , Vietnam , UAE , Africa , Germany , America , etc.

The PVC edge banding production line consist of automatic feeder , twin screw extruder , double output extrusion mold , embossing device , cooling calibration equipment , synchronized hauling off unit , glue coating device , winding machine , printing line , etc . compare with the normal single screw extruder , we adopt the twin screw extrusion line , it can feed the PVC powder directly , don’t need to produce the plastic granules first step , it will save the invest the pelletizing machinery , and reduce the production cost largely . and the double screw extruder can be made double output or four output , it increase the production capacity .

![]()

Main Technical Parameter of PLASTIC PROFILE PRODUCTION LINE/PLASTIC PVC PROFILE EXTRUDER/EXTRUDING LINE/EXTRUSION MACHINERY/MAKING MACHINERY

| Model | XPM45 | XPM51 | XPM65 | ||

| Product max size (mm) | 10-50 | 10-50 | 10-50 | ||

| Extruder | SJSZ45/90 | SJSZ51/105 | SJSZ65/132 | ||

|

Capacity (kg/h) |

60-80 | 80-150 | 100-200 | ||

|

Machine Length (m) |

12 | 13 | 14 |

![]()

PVC Edge Banding Extrusion line

we equip wtih the twin screw extruder for the PVC edge banding production , it can deal with the PVC powder directly , don't need to make the PVC granules in advance , it can reduce customer's investment . don't need the PVC granules making machine , also reduce the workshop area and worker labor .

the PVC edge banding has the characters as heat tolerance , oil proof , high hardness , abrasion resistant and excellent bendability , the surface can be printed different pattern , like the natural wood pattern or any other wonderful pattern , also the surface also can be laminating or hot stamping with different pattern . the PVC edge banding is recycled , environment-friendly .it’s wide use in furniture , cabinet , door or window , office furniture , shelf , machinery , etc .

![]()

Our Services

1. Before order: We will provide relevant information on various technology and business consulted by customers. If clients want to visit our company, we will offer all they need for convenience.

2. During order: company designs groundsill installation chart for water, electricity and gas of equipment basing on real condition and customers’ requirements and provides detail order list and matching manufacturer for reference for customer.

After equipment arrival, our service personnel will arrive at posted locale for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product. Service personnel have to arrive at customer’s locale in time when we provide service for client again.

3. After order: we will offer 12months after sales service freely, but our service will be life-long. if some parts are broken, we will send them by express, air or ship as soon as we can.