-

PE Pipe Extrusion Line

-

PP Pipe Extrusion Line

-

PVC Pipe Extrusion Line

-

PVC Profile Extrusion Line

-

Carpet Backing Machine

-

PVC Wall Panel Extrusion Line

-

PVC Edge Banding Machine

-

Goodyear Welt Machine

-

3D Printer Filament Production Line

-

WPC Profile Extrusion Line

-

PVC Floor Extruder

-

Artificial Marble Production Line

-

PVC Ceiling Production Line

-

Plastic Granules Machine

-

PVC Board Making Machine

-

PE Corrugated Pipe Making Machine

-

Table Cloth Machine

-

Plastic Tile Extrusion Line

-

Auxiliary Machine

-

PC Light Tube Line

3 Phase Plastic Profile Extruder PVC Edge Banding Machine Extrusion Line 380V

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Contactor Brand | Siemens | Raw Material | PVC |

|---|---|---|---|

| Color | Customized | Screw | Conical Twin Screw |

| Warranty | 1 Year | Inverter | ABB |

| Voltage | 220V,380V Or Customized | Application | Decorative Materials |

| Output | 50-100Kg/H | Motor Power | 37Kw |

| High Light | 3 Phase Plastic Profile Extruder,Plastic Profile Extruder 380V,PVC Edge Banding Extruder |

||

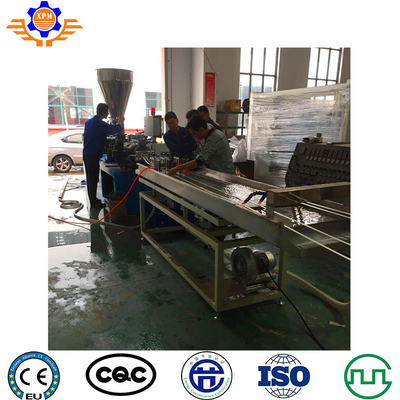

380V 3 Phase Plastic Profile Extruder Machinery for PVC Edge Banding Machine Extrusion Line

Plastic profile extruder / extrusion machine for PVC edge band

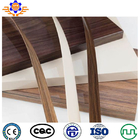

PVC edge band extruder / extrusion machine is used to produce PVC / WPC edge band.

PVC edge band width : 5mm-300mm

![]()

PVC edge band extruder / extrusion machine information:

Materials:PVC powder

1. Power supply: 380V / 3 phase / 50Hz

2. Installed Power : 70kw

3. Output :150kg / h

4. Production application: edge band

PVC edge band extruder / extrusion machine equipment list:

1. 51 / 110 double screw extruder one set

2. Die mould one set

3. Embossing machine one set

4. Cooling tank one set

5. Haul-off machine one set

6. Surface sizing unit one set

7. Winder one set

8. Electrical control unit one set

![]()

Technology and Service:

1. Seller supply full set of technical document, cutter and other full document (write in English).

2. Seller supply training for buyer’s staff until buyer can produce the eligible production independently.

3. Seller is responsible for installing, testing, adjusting and debugging the machines in buyer’s factory.

4. Buyer should pay the expense for our engineers including for our engineer including round-

way tickets, inland traffic, lodging and boarding fee when the machine is installed, tested and maintained.

5. Seller will go to install machines after the machine is arrived at buyer and buyer will have prepared all

conditions (including power, water, compress air, tools and materials for producing pipe, etc) for installing

and testing these machines. Buyer should pay 100USD/day.

6. When installing,people of both sides cooperate well and carefully,buyer supplies convenient working

condition,any problem, should discuss peacefully and kindly.

7. Buyer supply proper working tools, equipments and other conditions.

8. The expense including the accommodation and materials of the trial-

run the machine for testing and other expenses(electric, water, air and worker) will be on seller’s account,

if the buyer or their representatives do the inspection of the machines before shipment.

9. Guarantee period: 14 months after shipment (the date of B/L)